Improving CMM productivity with Automation

Loading and unloading are some of the most tedious tasks and, in many cases, the bottleneck during automated metrology inspection.

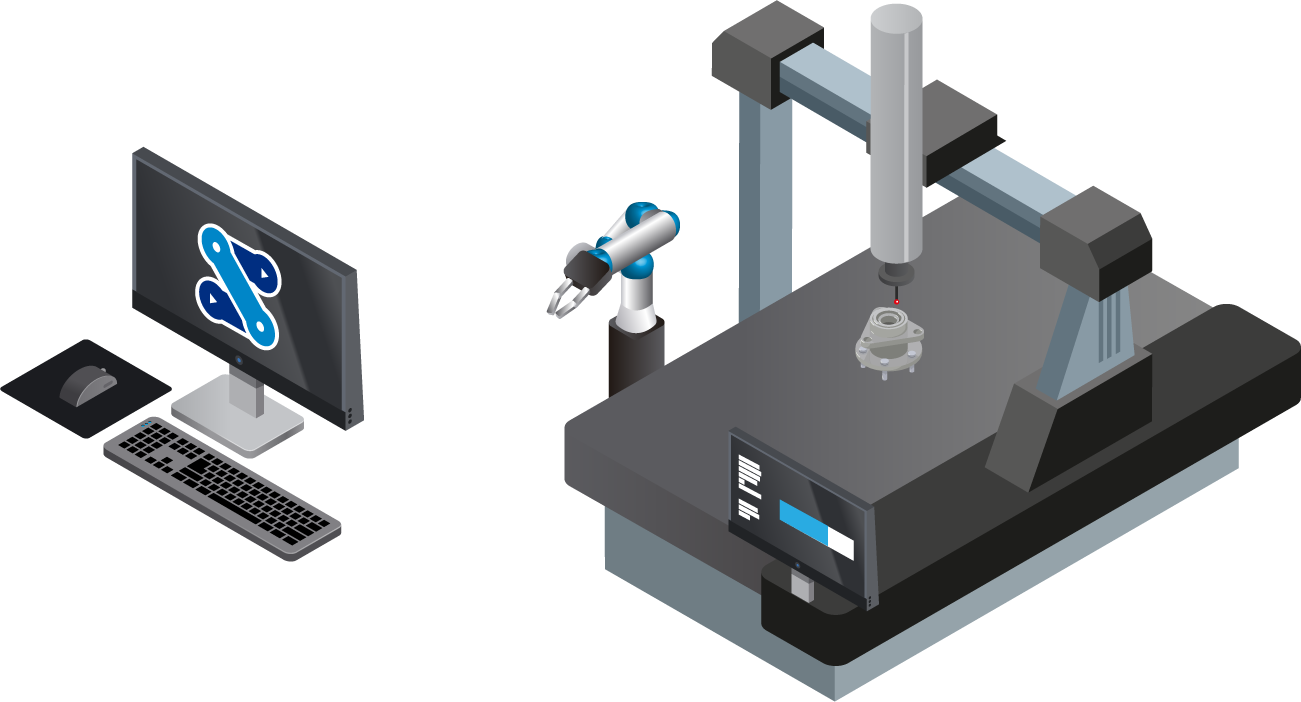

By adding collaborative robots to the inspection process, you can increase inspection speed significantly. Collaborative robots are easy-to-use and won't require specialized personnel. You can trust that the multi-part inspection will be done automatically.

This process is also known as machine tending.

Fast and High ROI

CMM Tending frees the operator from repetitive tasks, allowing him to execute additional activities or even scale up to several CMMs simultaneously; this means you can make more in less time and with fewer people.

Streamline automation software is the core of the machine tending system; it provides seamless integration between robots, PolyWorks|Inspector, and your coordinated measuring machine.

You don’t need a specialized robot programmer, Streamline software provides an interactive common interface amongst all hardware.

Safe

The robots integrate collision detection and safety sensors, the machine tending systems can work side by side with people.

Greatest Value

Highest productivity and lowest cost by saving time on repetitive tasks with high repeteability.

Benefits of CMM Tending

Remove the load and unload bottleneck

Increase in productivity

Highly repeatable

Decrease manufacturing costs

Multi-CMM support

Increase staff satisfaction

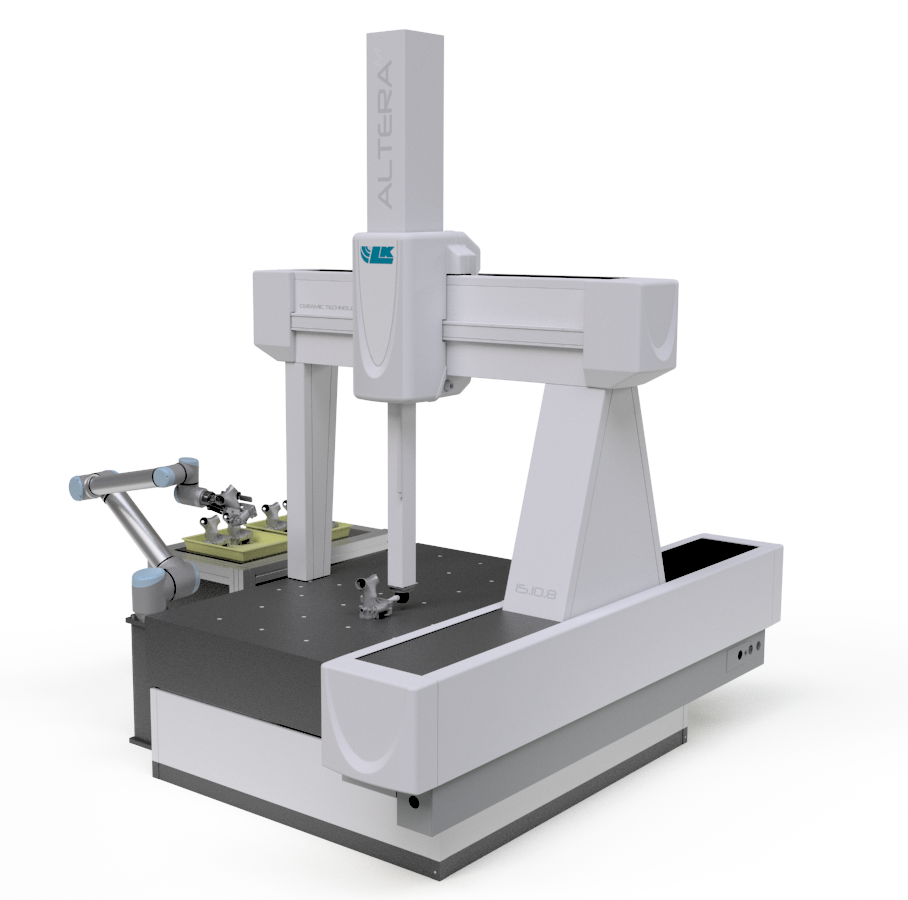

Our machine tending solutions are compatible with the leading CMM brands

Streamline automation software is the core of the machine tending systems, it provides clean integration with most of CMM's brands and robots.

3D Dimensional Analysis and Quality Control

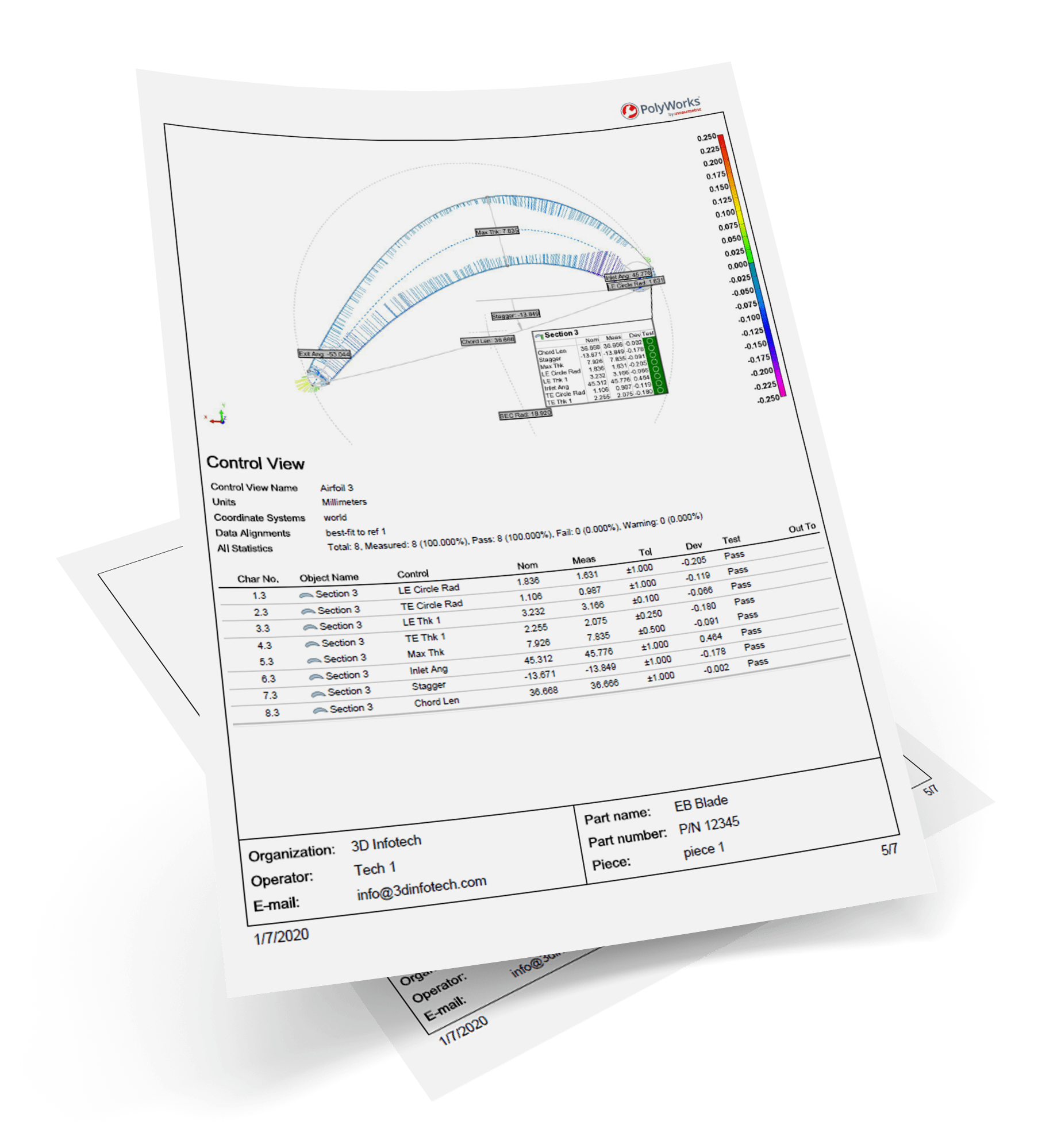

PolyWorks|Inspector™ is a 3D dimensional analysis and quality control software to verify part dimensions, diagnose and prevent manufacturing and assembly issues. At the heart of PolyWorks|Inspector lies a powerful inspection engine with parametric data handling, certified mathematical algorithms, and extensive visual and audio feedback capabilities.

Driven by Streamline

A touchscreen user interface provides a friendly solution that is secure and permission-based.

Driven by Streamline

A touchscreen user interface provides a friendly solution that is secure and permission-based.

Processes

Injection Molding

CNC Machining

Metal Die & Stamping

Sheet Metal Forming