Professional Reverse engineering

Our Reverse engineering service is the most efficient way to obtain CAD files from physical objects. Using 3D scanning or probing, we generate a 3D model that matches the original and, if required, a parametric model ready to be modified in SolidWorks.

We are the master distributor of PolyWorks, and the developers of Point2CAD, the leading reverse engineering software for portable CMMs. No other company has the experience and knowledge we have in Reverse Engineering.

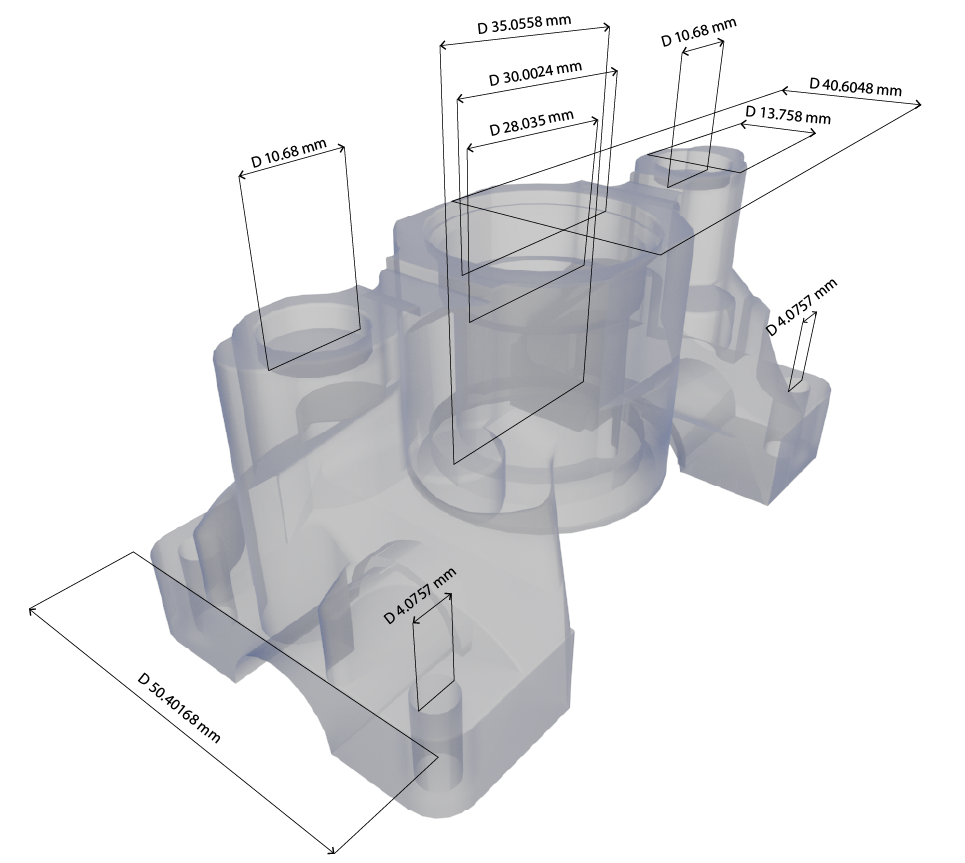

3D Infotech can provide multiple methods and services to define your parts or tools. We can deliver various stages of the reverse engineering process from raw point cloud data to fully dimensioned and toleranced parametric, freeform, or hybrid (combination of parametric and freeform geometry) CAD models and drawings.

No matter the size of your part, we can reverse engineer it

What we can do for you

Get the model you need

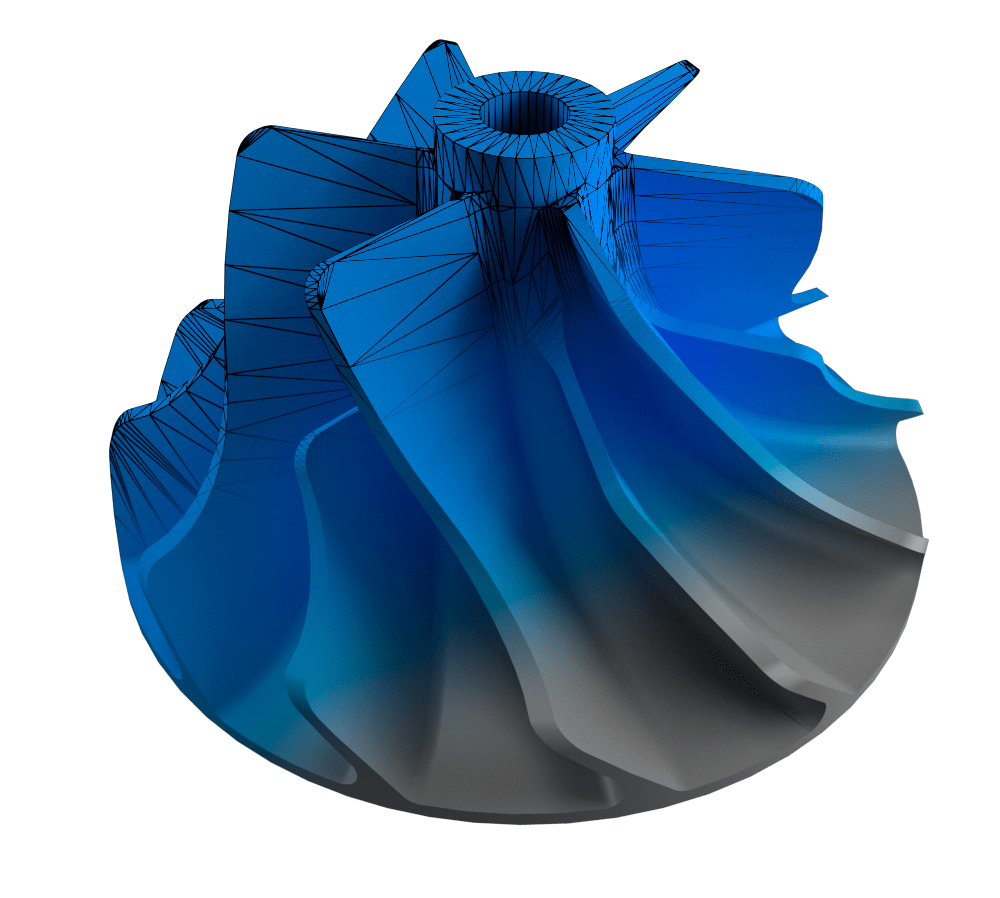

Lowest deviation and a high fidelity model of your part

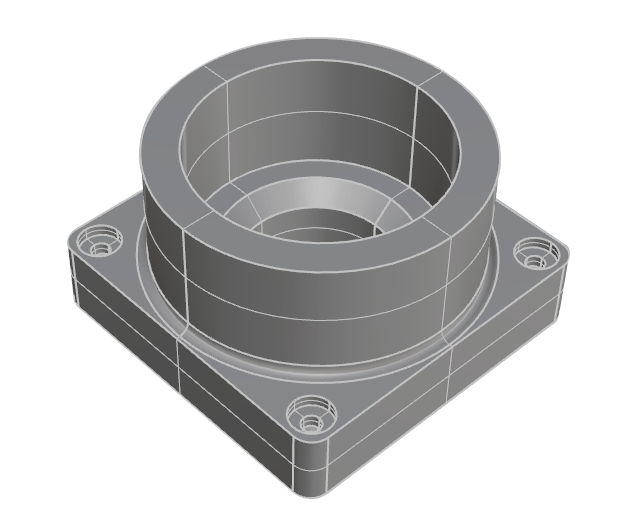

With Solid Modeling we will get the smallest deviation from your original part. This is a high accuracy reverse engineering process, easy to be shared with all your manufacturing areas due the small file size and neutral CAD for almost any 3D software (STEP, IGES).

With solid surface modeling you will manufacture exactly the same part you need.

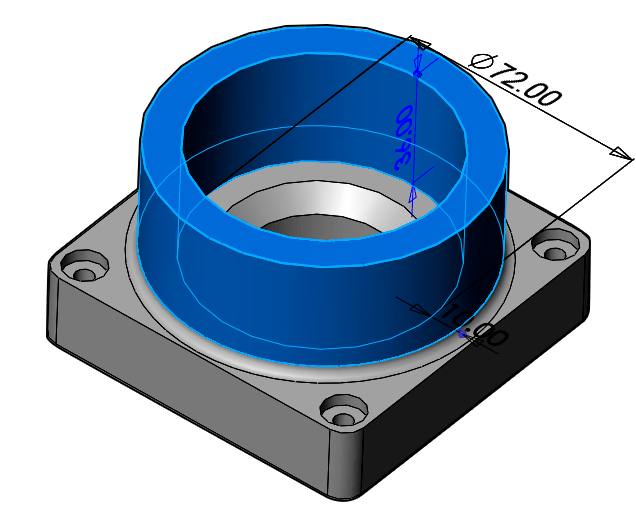

Modify your reverse engineered part in SolidWorks

Parametric modeling is extremely useful for products that are driven by dimensions. With the parametric approach, engineers can quickly and easily create different configurations of their designs.

The parametric modeling can include dimensions, pattern instances, wall thicknesses, hole diameters and depths, and so on.

Reverse Engineering Methods

3D Scanning

Useful for most types of parts, small or large. We have different scanners to use in each case; some scanners require targets others don't; some parts are shiny or black and required the latest blue laser technology. In very special cases, the part has deep pockets or holes that be measured using probing.

3D Probing

Useful for transparent objects that can't be 3D scanned. Objects with sophisticated deep features inside where the light of a traditional 3D scanner won't reach. Or prismatic parts that can easily be reverse-engineered feature by feature directly in PolyWorks.

CT Scanning

In a part with many inner cavities, Computed Tomography can produce the necessary data to solve the most complex designs while you save a significant amount of time, costs and effort.

Utilizing industrial CT scanning, we can correct, optimize, and capture part data to reproduce parts and enable tasks like tool correction and mold validation even if the CAD model never existed.

The best engineers using the best technologies

Because we are the Master Distributor of PolyWorks in the West Coast, our engineers are not your average metrologist; they are high-level trainers and consultants with years of experience.

No matter the challenge of your project, our team will achieve the best result.

Applications for Reverse Engineering

All our equipment is OEM purchased and certified to meet quality standards.

Each equipment is maintained and certi ed to manufacturer’s speci ed requirements. Our engineers and technicians alike have had professional training and on-the-job work experience using these devices, with the ability to perform initial trouble-shooting if necessary.

FARO

- Faro Edge

- Faro Quantum

- Faro Focus

- Faro Tracker

LMI

- Gocator 3506

- Gocator 2520

Customer References

Processes

Injection Molding

CNC Machining

Metal Die & Stamping

Sheet Metal Forming

Need Inspection and Quality Control?

To learn more about our inspection services, click on the link below!