Smart Factory On-Site Inspection

Modular

Motorized Rotary

Safe

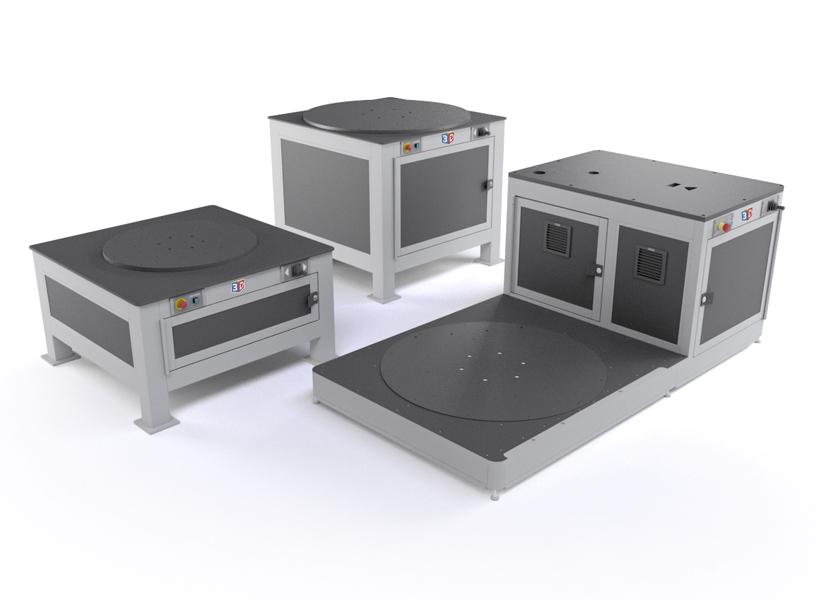

Flexible Rotary Options

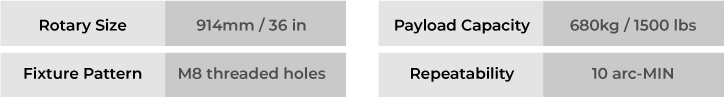

General Specifications

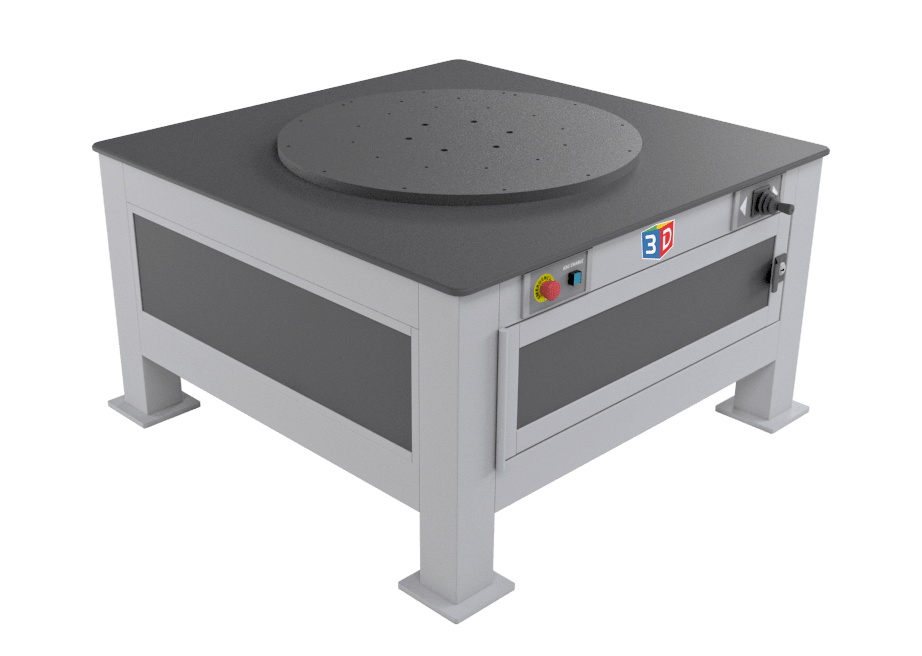

High Profile

Rotary Table

- 940 x 940 x 857mm

- Payload: 680kg / 1500lbs

Low Profile

Rotary Table

- 940 x 940 x 555mm

- Payload: 680 kg / 1500 lbs

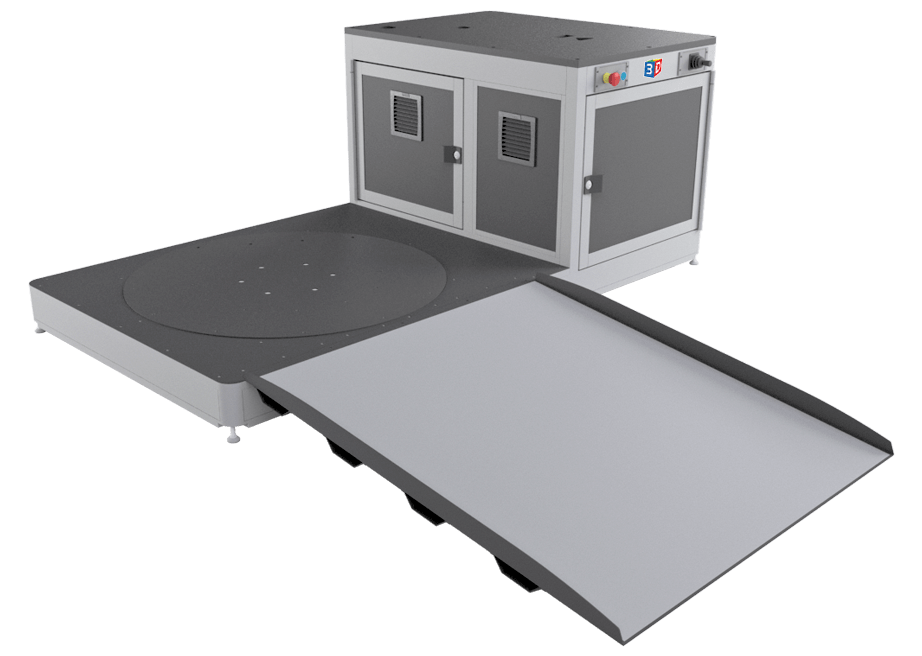

Ultra-Low Profile

Rotary Table

- 1900 x 1000 x 750mm

- Payload: 680 kg / 1500 lbs

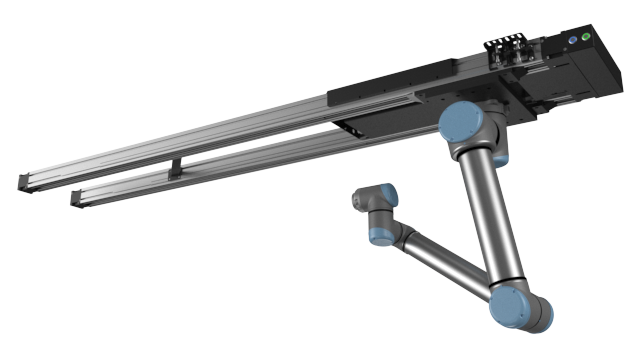

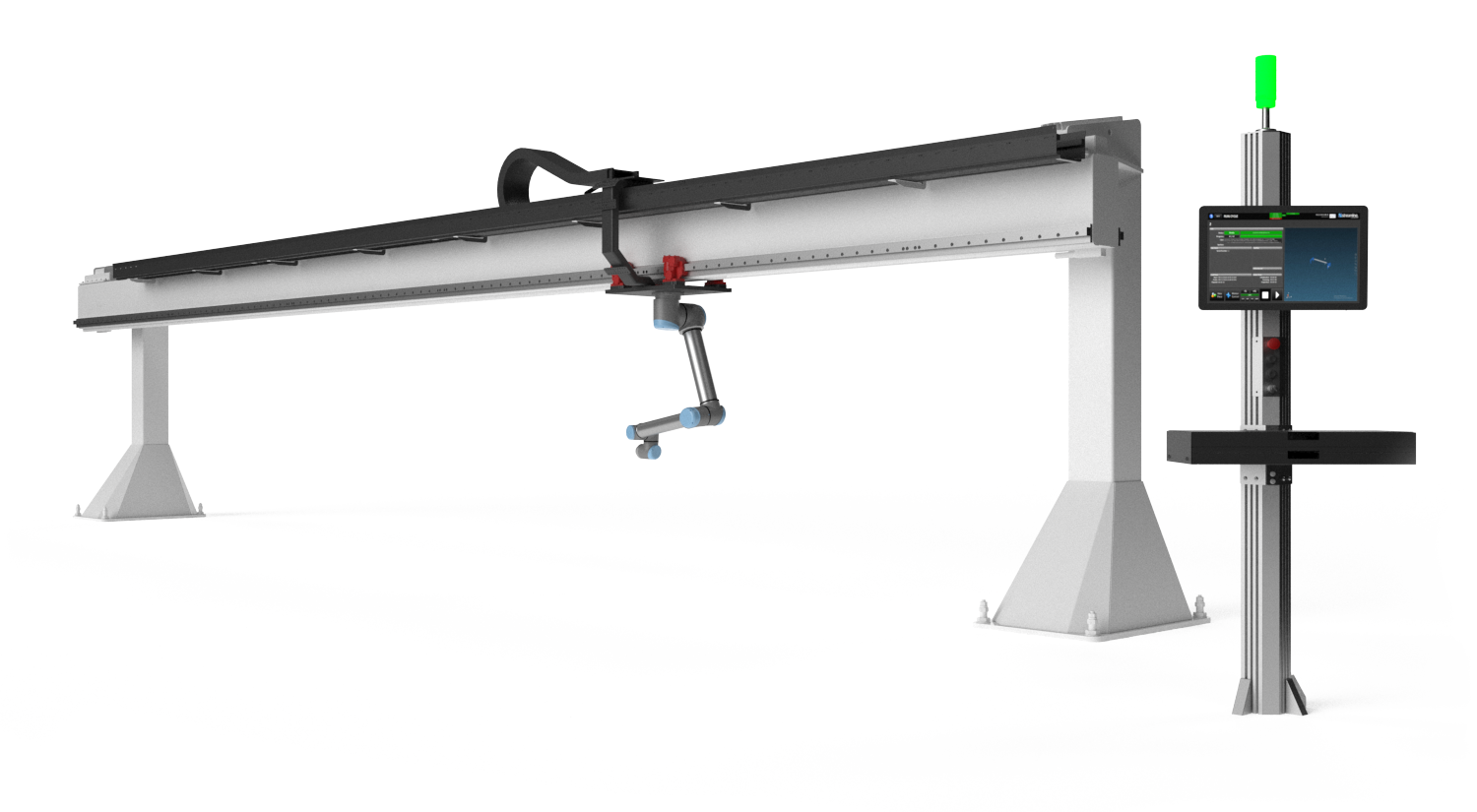

Seventh Axis Motion

When parts are longer, and the standard solution is not enough, we have designed two rail systems that work as a seventh axis for the robot.

Top Mount Rail System

Long Form Rail System

Call now to Talk with an expert

+1 (949) 988-0200

Core Advantages

2D and 3D Sensors Flexibility

Both UMA Smart Station models are compatible with a wide variety or 3D scanners and 2D sensors. They can be equipped to become and optical CMM or a visual inspection station.

Explore the scan quality!

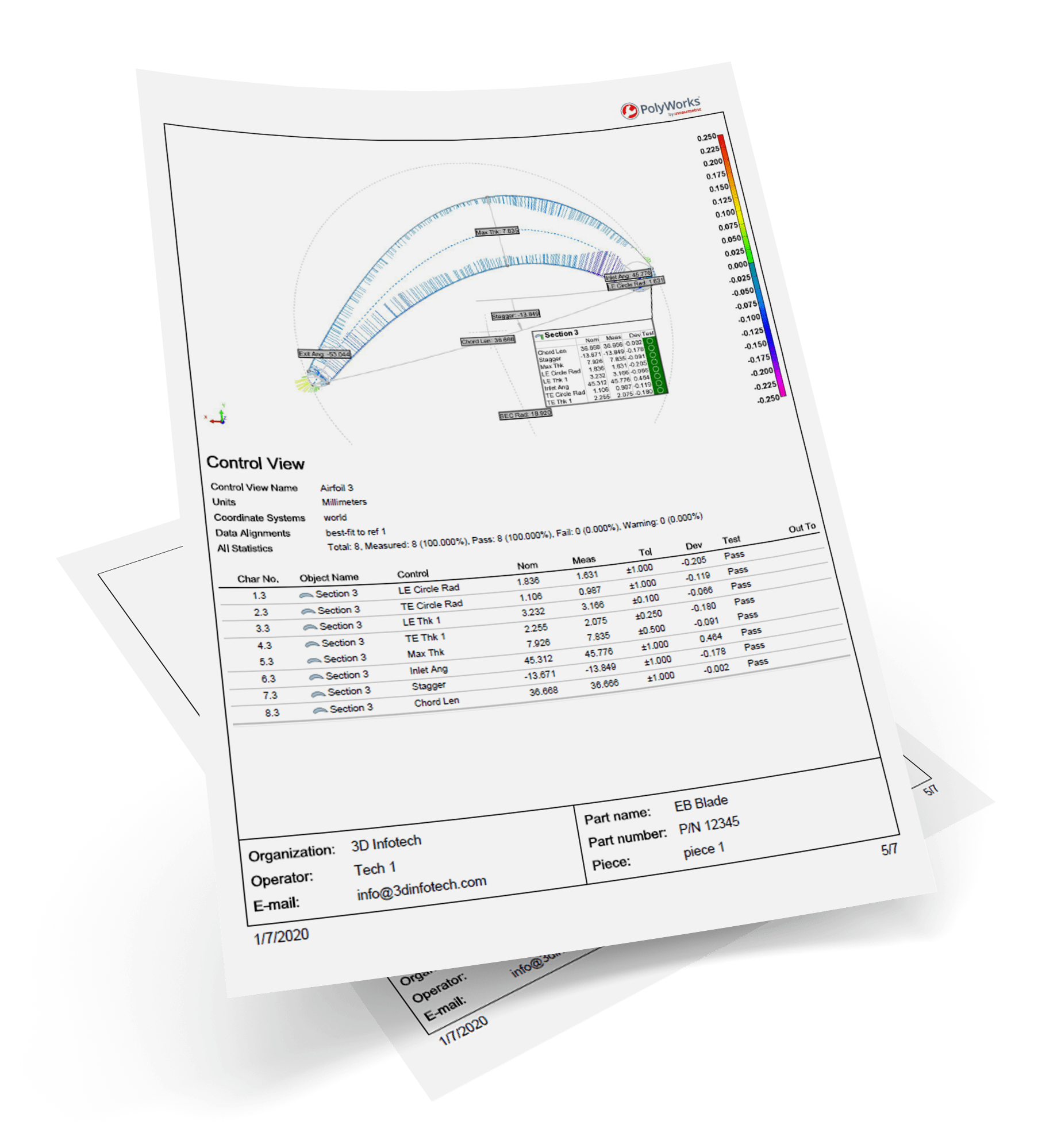

3D Dimensional Analysis and Quality Control

PolyWorks|Inspector™ is a 3D dimensional analysis and quality control software to verify part dimensions, diagnose and prevent manufacturing and assembly issues. At the heart of PolyWorks|Inspector lies a powerful inspection engine with parametric data handling, certified mathematical algorithms, and extensive visual and audio feedback capabilities.

Driven by Streamline

A touchscreen user interface provides a friendly solution that is secure and permission-based.

Driven by Streamline

A touchscreen user interface provides a friendly solution that is secure and permission-based.

Call now to Talk with an expert

+1 (949) 988-0200