Fast and Flexible

Two options to fit the needs of your business

Portability

All in one

You don’t need a specialized robot programmer, Streamline software provides an interactive common interface amongst all hardware.

High Speed

Integrated with laser or structured light scanners, this station have faster cycle times compared to any other system.

Greatest Value

Highest productivity and lowest cost compared to traditional 3D scanning and Coordinated Measuring Machines (CMMs)

Core Advantages

Accuracy

Speed

2D and 3D Sensors Flexibility

Both UMA Smart Station models are compatible with a wide variety or 3D scanners and 2D sensors. They can be equipped to become and optical CMM or a visual inspection station.

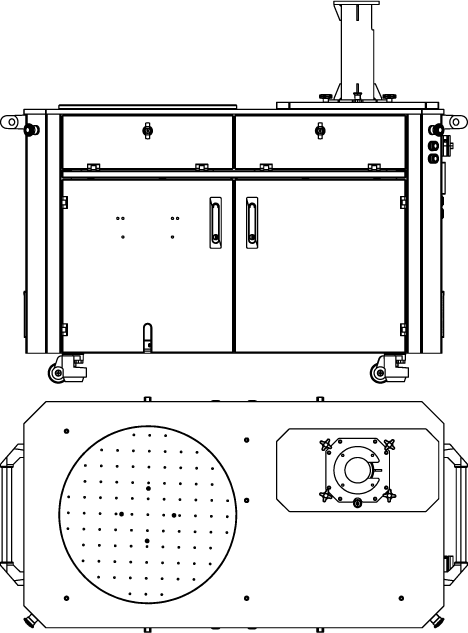

Smart Station 2x4 | 2x4 ft. |

|---|---|

Rotary Table Size | 559 mm (22") |

Rotary Payload Capacity | 100 kg (220 lbs) |

Product Dimensions without Robot | 1470 x 735 x 875 mm |

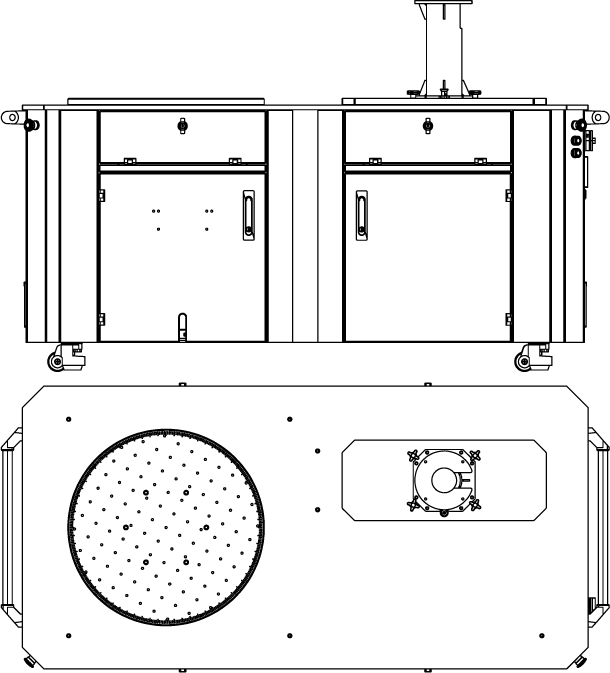

Smart Station 3x6 | 3x6 ft. |

|---|---|

Rotary Table Size | 635 mm (25") |

Rotary Payload Capacity | 315kg (700lbs) |

Product Dimensions without Robot | 1970 x 920 x 1014 mm |

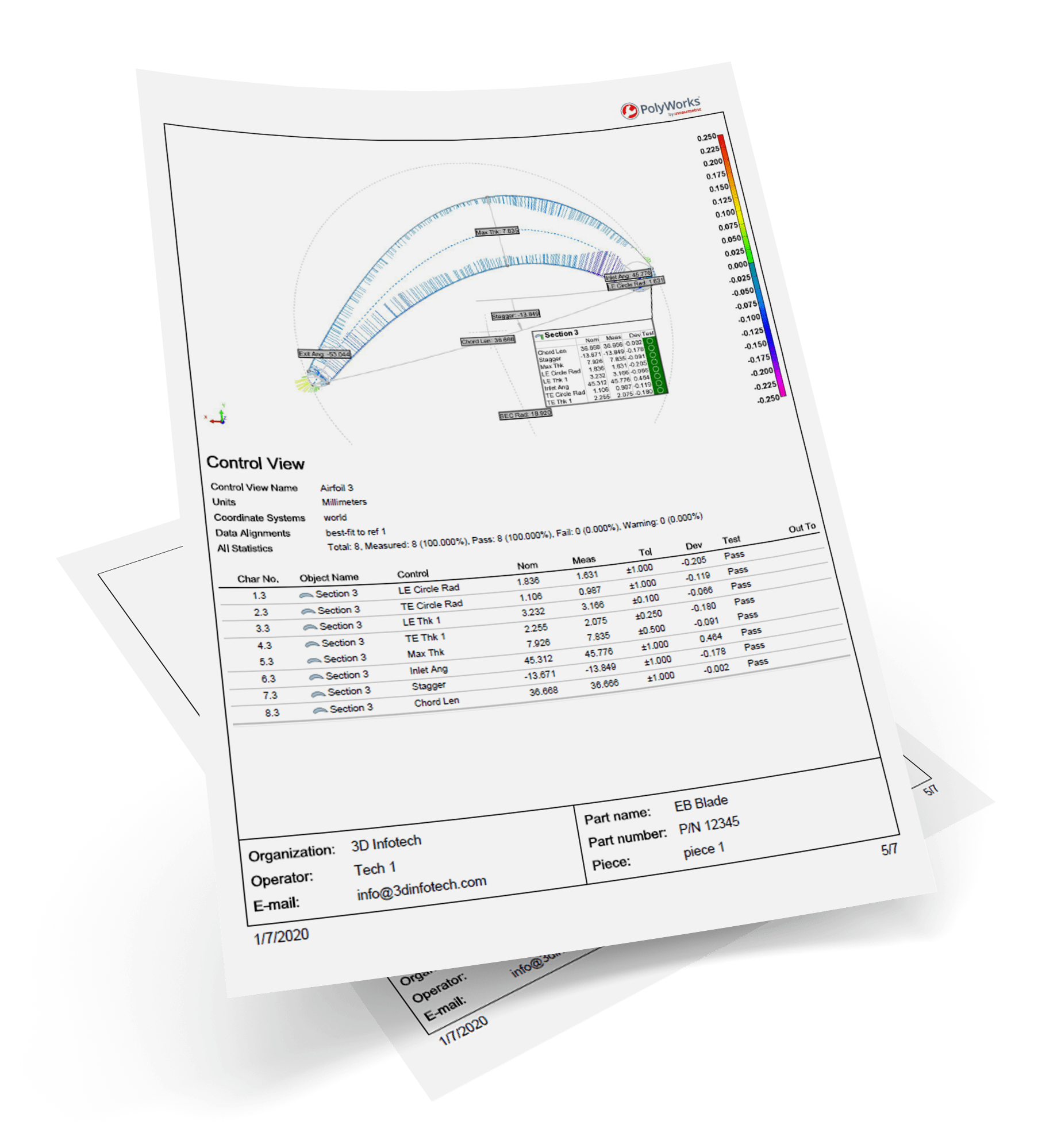

3D Dimensional Analysis and Quality Control

PolyWorks|Inspector™ is a 3D dimensional analysis and quality control software to verify part dimensions, diagnose and prevent manufacturing and assembly issues. At the heart of PolyWorks|Inspector lies a powerful inspection engine with parametric data handling, certified mathematical algorithms, and extensive visual and audio feedback capabilities.

Driven by Streamline

A touchscreen user interface provides a friendly solution that is secure and permission-based.

Driven by Streamline

A touchscreen user interface provides a friendly solution that is secure and permission-based.

Processes

Injection Molding

CNC Machining

Metal Die & Stamping

Sheet Metal Forming