Guided Part Placement

Is this the right solution for you?

Speak with us today!

The right part in the right place

It works with tight tolerances on angles and orientations with a measured level of confidence for accurate part placement.

Part position outline, direction arrows and measured confidence levels.

Versatile

Easily integrates with more than 50 camera models

Compatibility

Supports communication protocols 3rd party applications.

Augmented Reality Assisted Placement with Real-Time feedback

PartID’s functionality extends to any process that requires, location, dynamic guidance, object presence, or assembly verification.

When placement is vital to execute a task, get a consistent result without complex fixtures, and reduce human error when working with manual placements.

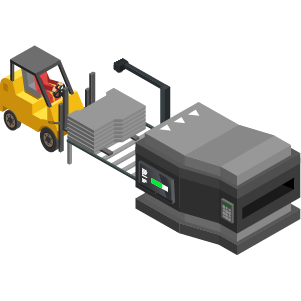

Part ID is excellent for applications like loading metal sheets for clamping, stamping, or bending machines. Verify the correct position or orientation to reduce scraps or unexpected results.

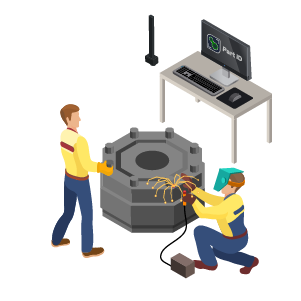

Verify the presence of any object before starting an action. Validate if an assembly has the component in the correct location to start drilling, fastening, or welding.

Watch and learn how PartID works

Rapid implementation and immediate results by non-technical personnel.

Live part placement verification

Users can validate in real-time what they are doing with a live feed with helpful overlays.

Part ID feature tools to check elements like:

Shape, Position or Orientation of an object

Sort and organize the hundreds of dimensional and GD&T results into compact and well organized groups of controls, if required you can tie them to specific alignments and coordinate systems.

Presence or abscence of elements in a part

Global list of controls sorted by characteristic index, and display critical results in 3D with the preferred point of view for easier dimensional analysis and reporting.

Verify Labels or Part Numbers

Analyzing trends and behaviors of multiple pieces to take smart manufacturing decisions.

Applications

Extended functionality to any process

- Placing parts for dimensional inspection

- Loading stacks of sheet metal on stamping machines

- Placing material for punching and bending

- Validating if a door is closed or open before processing

- Validating if an assembly has all components and in the correct location

KEY FEATURES

- Extremely easy to use, meant for non-technical users.

- Highly optimized, single purpose tool

- Works with a variety of camera models and lenses

- Easy to integrate with other software using the command line

- Works in two user levels, Engineer Mode with full access to teaching parts and Operator Mode to view and validate.

KEY FEATURES

- Extremely easy to use, meant for non-technical users.

- Highly optimized, single purpose tool

- Works with a variety of camera models and lenses

- Easy to integrate with other software using the command line

- Works in two user levels, Engineer Mode with full access to teaching parts and Operator Mode to view and validate.

Processes

Injection Molding

CNC Machining

Metal Die & Stamping

Sheet Metal Forming