Computed Tomography (CT) Scanning

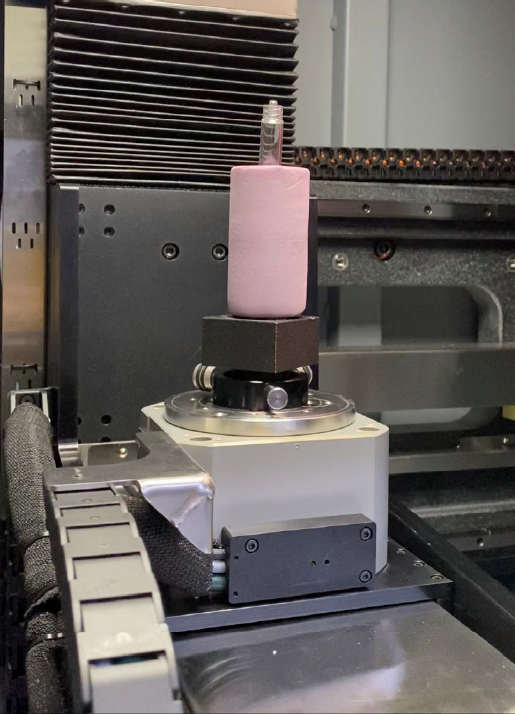

CT Scanning is a non-destructive inspection service that 3D Infotech provides. It offers a complete inspection of your part's internal and external structures, like an industrial X-Ray.

Is this right the right solution for you? Chat with us >

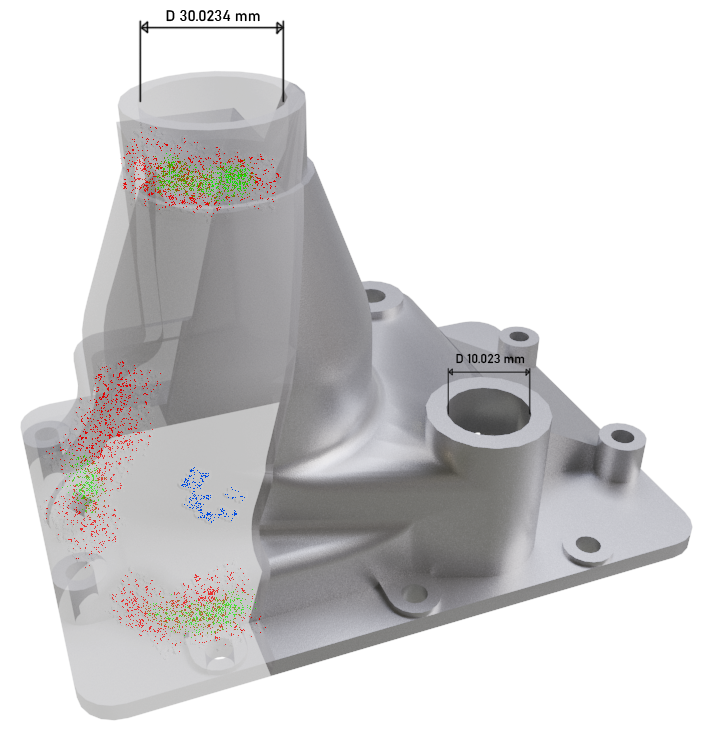

CT Scanning makes hidden things visible

Ever wished you had a way to inspect the internal geometry of a part or assembly without having to destroy your expensive part or assembly?

You can take full advantage of our CT scanning services to solving your dimensional inspection and evaluation challenges without the cost associated with an industrial CT scanning system.

Scan, analyze and inspect the core of your components that cannot be detected with any traditional CMM.

With a quick CT scan, every structural and dimensional aspects of a part can be revealed in a non-destructive way

CT Scanning allows full inspection capability of internal geometry without dissasembly, touching or accidentaly damaging a part.

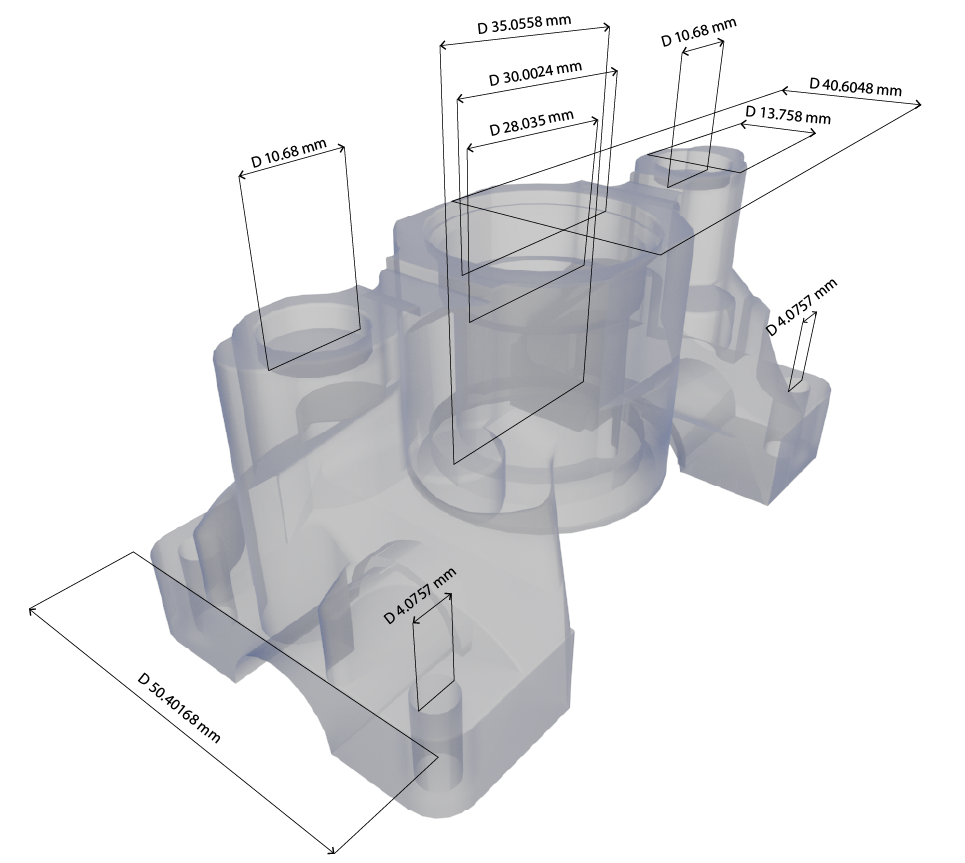

The process creates 3D data sets which allows the analysis of dimensions, porosity, thickness, assembly defects, assembly control, testing or reverse engineering.

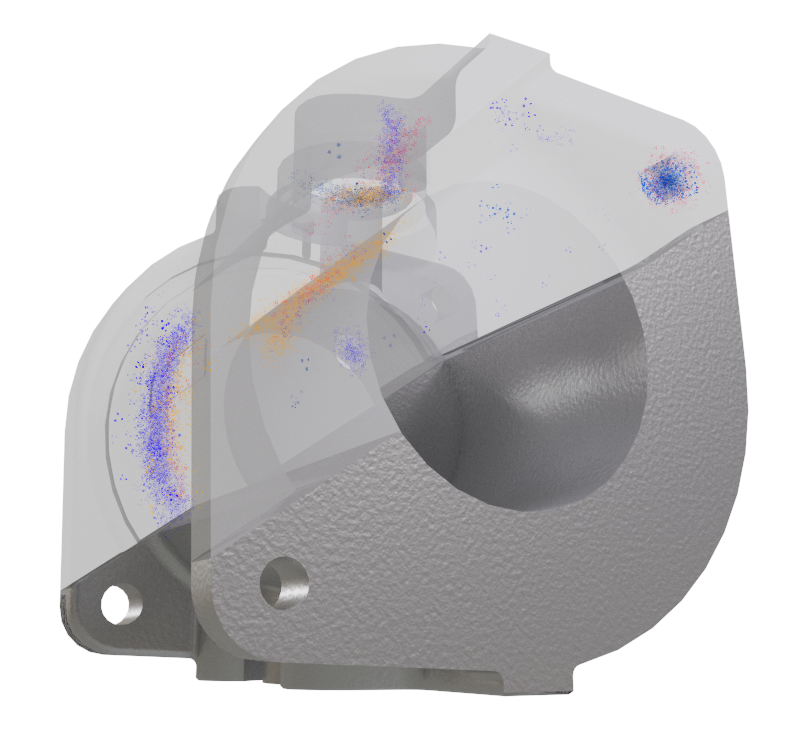

Reveal the hidden structure of your scan

Slice the scan to analyze, measure or inspect the assembly of your components even without a CAD.

With our CT Scanning services you can find:

And many more...

Talk with an expert to know how CT Scanning can help in your industry

Call now to Talk with an expert

+1 (949) 988-0200

Reverse Engineering?

Of course!

Computed Tomography can produce the necessary data to solve the most complex designs while you save a significant amount of time, costs and effort.

Applications for CT Scanning

Non-destructive (NDT)

Model Comparison

Thickness Analysis

Reverse Engineering

Dimensional Control

Measurement analysis and geometry comparison

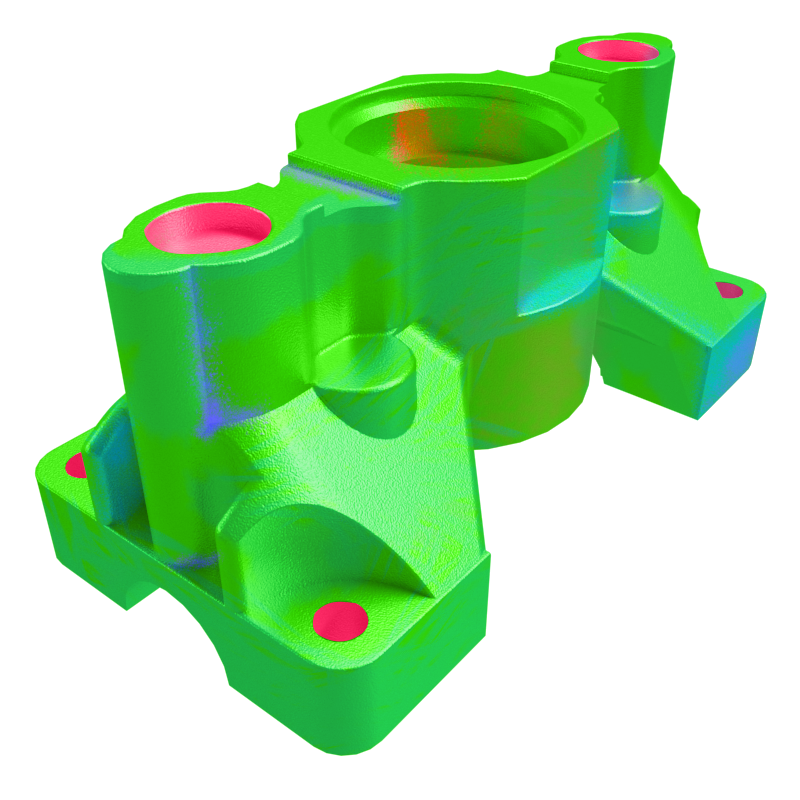

Defect Inspection

Assembly Control

Joining analysis

Testing

Example Applications

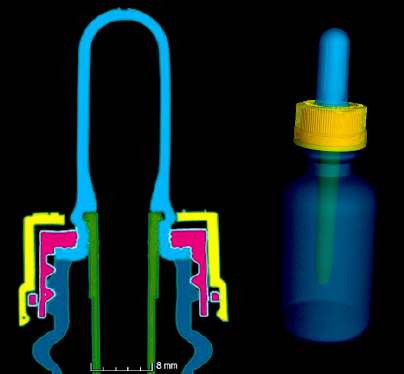

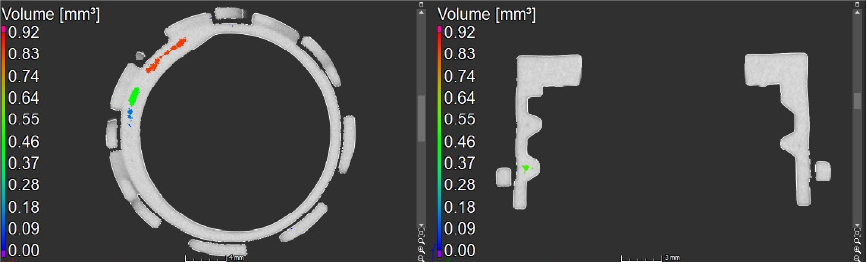

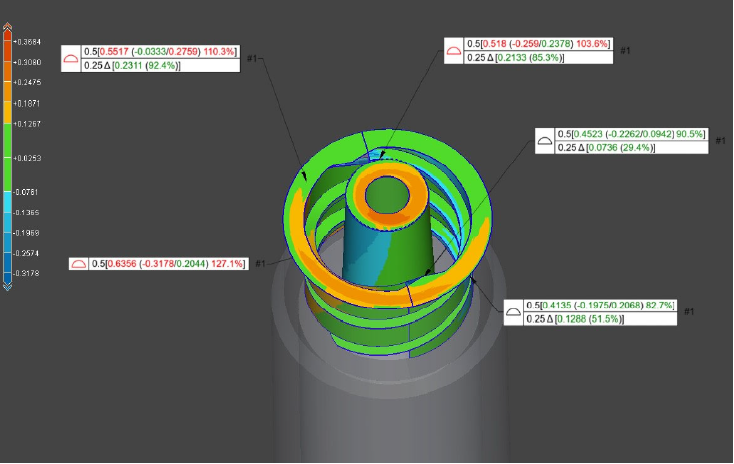

Dropper Bottle Cap Seal Assembly

In this application:

Assembly Control

Thickness Analysis

Volume

Wall Thickness

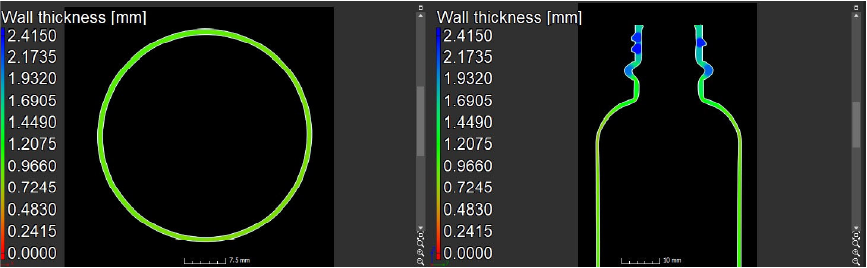

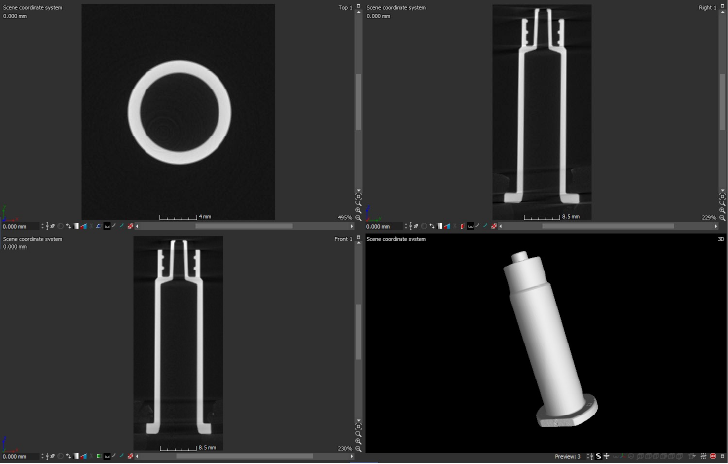

Luer Fitting

In this application:

Defect Inspection

Dimensional Control

Volume

Wall Thickness

Processes

Injection Molding

CNC Machining

Metal Die & Stamping

Sheet Metal Forming