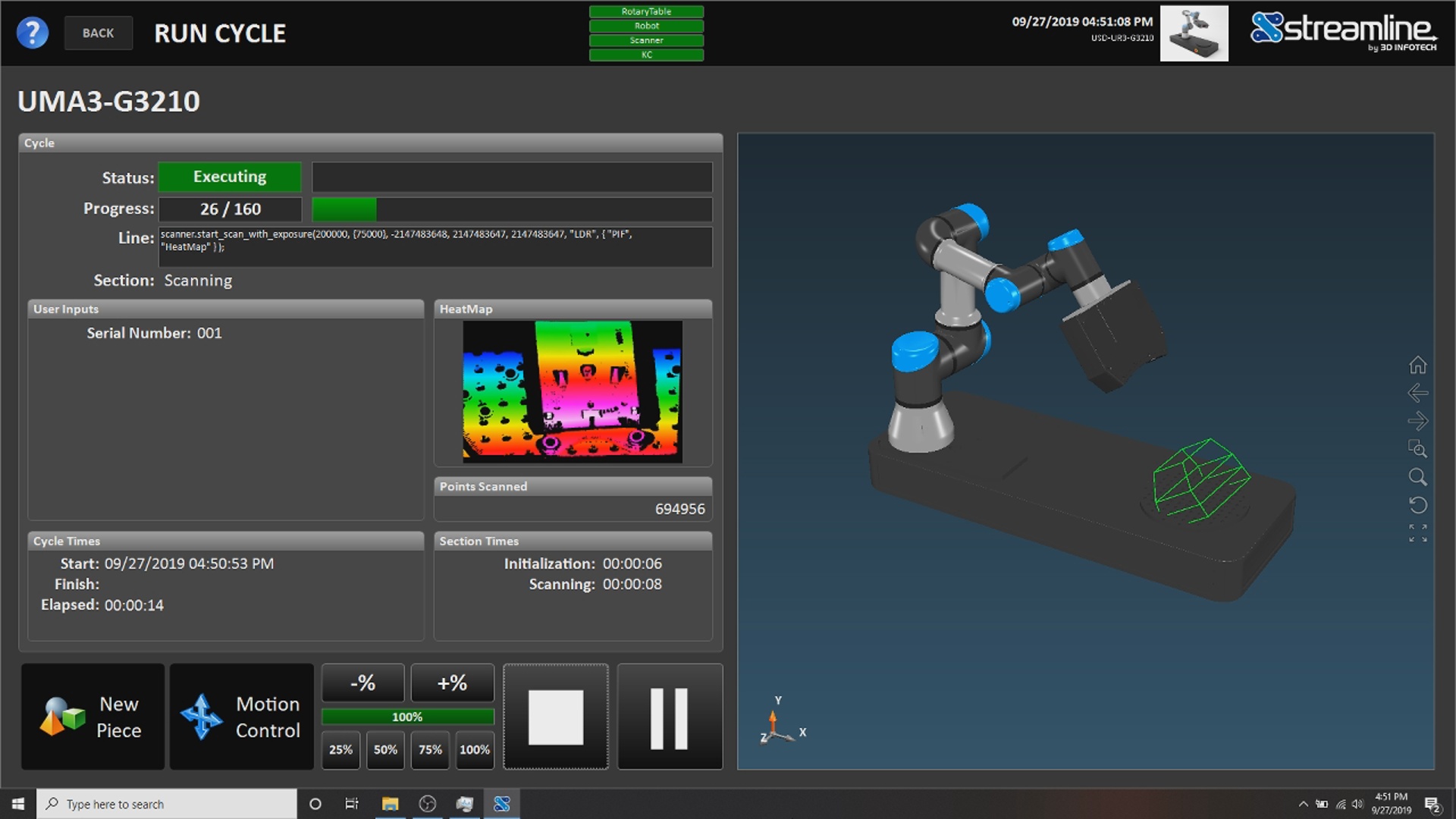

Streamline: Inspection Automation Software

Streamline Automation Software orchestrates hardware and software into a seamless inspection process. It takes care of all the complexities of robot programming, integration, and interoperability between devices and software. It anables you to optimize inspection, speed, and productivity.

Streamline software is a production-proven tool with successful installations at some of the most demanding customers in many industries like aerospace and automotive.

Everything you need is already built-in Streamline or through integration with powerful software and hardware tools. Streamline is a product that saves time, expenses, and headaches of trying to implement a prototype with custom code and scripts.

Wide device compatibility

Pair a 2D or 3D machine vision sensor with a variety of robot brands and motion control devices like rotary stages, linear rails, and so on.

Simplified Workflow

With two modes available, any operator with minimal training can run inspection tasks with a single click (or touch if using a touchscreen!).

Not limited to 3D Scanning

Use it in other areas, like automating the load and unload of a CMM inspection with a robot, visual verification of the presence and absence of components, or anything else you can automate!

From Project to Product: The Compatibility Challenge

Problem

In the past, you would see this: "In theory, it should work" This is what your system integrator would say for this type of projects. Traditional robotic inspection solutions are custom built, experimental, and prone to dead ends. There is a learning curve, and requires considerable time to master until you establish a production ready system.

Solution

When you implement Streamline, each of the preset configurations have been carefully tested for robustness and compatibility. You can be sure that the robot, motion control, sensor, and inspection software have been tested and are compatible.

Learn how Streamline works

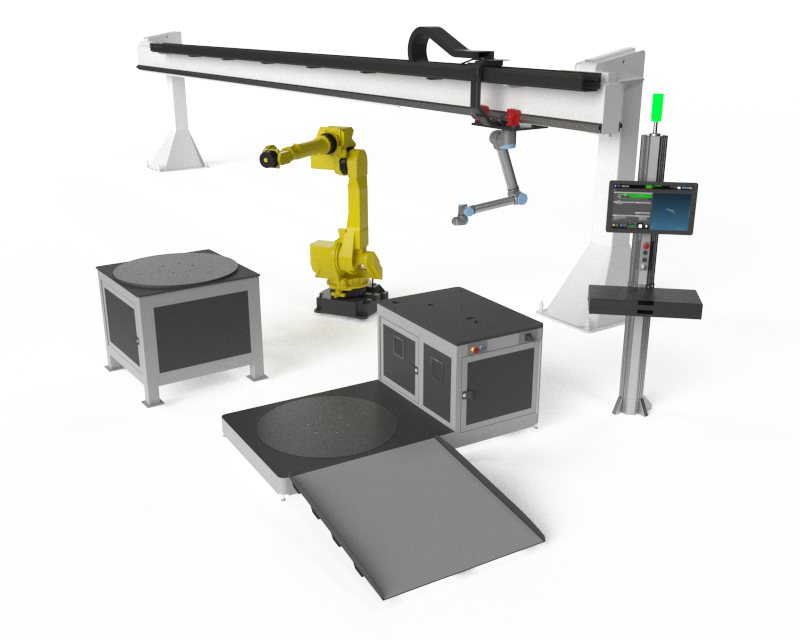

Streamline software centralizes all the components of your work unit (robot, linear rail, sensor, etc.) and synchronizes them with the software that you're using to analyze the data to run the complete task.

Streamline comes with two predefinied profiles: Operator mode and Editor mode, both include different permissions so engineers can easily program full tasks and the operators only need to press a button to start working.

Watch the video below to learn more about how Streamline works in the factories!

Streamline comes with two predefinied profiles: Operator mode and Editor mode, both include different permissions so engineers can easily program full tasks and the operators only need to press a button to start working.

Watch the video below to learn more about how Streamline works in the factories!

Streamline Software Implementation

A. Choose your inspection device.

Streamline is the heart of your inspection system; it has the tools to program and deploy automated inspections using the following data acquisition devices:

- 3D Scanners

- 2D Machine Vision Cameras

- Traditional CMMs

- Laser Trackers

B. Choose the type of motion system.

Once you have selected your data acquisition device, the next thing is to choose the motion control method. Streamline is optimized for robots, rotary tables, and linear rails out of the box, and it can work with many other configurations and external devices. Our preset configurations already have ideal combinations that will work for most cases.

In the case of traditional CMMs, data acquisition and motion control are traditionally automated. Streamline extends its automation by providing machine-tending tools; this means that the parts are placed in the CMM by a robot. The complete process is done automatically for many pieces, from placement to inspection.

In the case of traditional CMMs, data acquisition and motion control are traditionally automated. Streamline extends its automation by providing machine-tending tools; this means that the parts are placed in the CMM by a robot. The complete process is done automatically for many pieces, from placement to inspection.

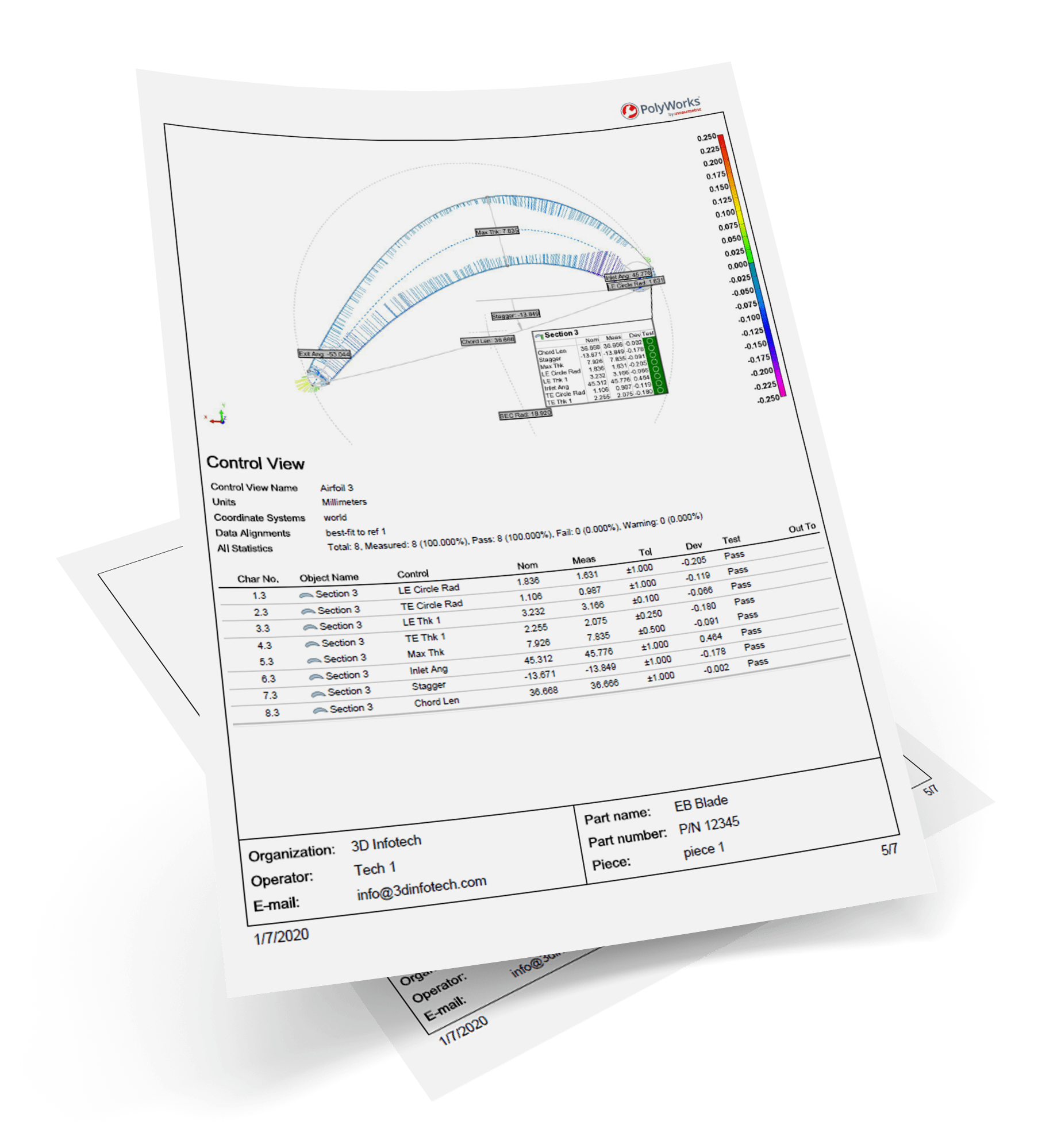

C. Inspection and Delivery

Once data has been acquired, the information is analyzed, and results are delivered. Depending on your device, you can choose the following software:

3D scanning and CMM probing

PolyWorks Inspector by InnovMetric is the preferred point cloud and mesh analysis tool. Streamline has been optimized to work with it in many aspects. PolyWorks has a complete set of tools for analysis, GD&T, SPC, and reporting.

2D Machine Vision

For 2D inspection, Streamline can capture images with a machine vision camera and forward them to any analysis software, from custom tools to deep learning software like Cognex ViDi. It is also optimized to work with Cognex In-Sight Smart cameras, where all the software analysis is done in the embedded computer of the camera.

For more specialized crack analysis, Streamline works directly with our die penetrant inspection camera.

For more specialized crack analysis, Streamline works directly with our die penetrant inspection camera.

Streamline, The most flexible inspection automation software

Learn One, Deploy Many

When you choose Streamline, you just need to learn one software to solve very different inspection challenges. Different parts, large or small require different sensors and brands, consistency will boost your productivity by having a unified workflow among your off-line and at-line inspection systems.Features

Workflows

- Part management

- User access control

- Automatic template setup

- Live 3D View

- Realtime preview with selected devices.

- Custom workflows triggered by badge readers and barcode scanners.

- Simplified operator mode or kiosk mode

- Optimized for touchscreens.

- Optional PartID interactive placement and validation with machine vision.

- Multi-language support: English, Chinese, Spanish, Korean, and Portuguese (more languages coming soon)

Technology

- 3D scan robot kinematics

- Easy scripting language

- Off-line simulation with RobotDK integration

- Direct control and preview of compatible sensors

- Multiple 3D alignment options: IM Align, Inspector Alignments, or 3D Infotech's AICP fast alignment.

- External execution of command line programs with feedback control.

Hardware Integration

- Tight integration with Universal Robots, including remote execution of UR programs.

- Exceptional support for LMI Technologies' sensors and its embedded measuring tools.

- Automatic calibration for compatible devices

- PLC communication with Allen-Bradley ControlLogix, Micro 850, and SoftLogix 5800.

- Unique integration with optical motion tracking systems

- Direct support for devices:

- LMI Technologies

- Hexagon

- Zeiss

- Cognex In-Sight

- FLIR / Point Grey

- Direct support for Fanuc LR Mate 200iD, R2000, and M710

PolyWorks Metrology Suite software integration

- PolyWorks Dataloop Integration

- Remote execution of macros

- Microsoft SQL Server integration through the PW2SQL plugin

- Extended device support through PolyWorks plugin:

- Arms: Faro, Hexagon/Romer, Nikon, Mitutoyo, CimCore, Kreon, RPS Metrology, Tomelleri-SpaceArms, TTS Vectoron

- Handheld, optically tracked devices: Aicon, Geodetic, Metronor, Nikon, NDI, Zeiss

- Laser trackers: API, Faro, Leica

- Manual CMMs: I++, Deva, MZ1060, Renishaw, Samsoft, Wenzel

- CNC CMM controllers, through direct drivers: Brown & Sharpe, Coord3, DEA, Leitz, LK Metrology, Mitutoyo, Pantec, Sb-Elektronik, Wenzel

- CNC CMM controllers, through Zeiss CMM-OS: Zeiss

- CNC CMM controllers, through I++: All brands

- Theodolites: Leica TDRA6000

Cognex In-Sight hardware/software integration

- Job execution

- Camera control and preview

- Result management

Contact our metrology experts, they will be glad to help you find the best solution for your industry