An extensive array of dimensional inspection services and products

Process verification

First article inspections

SPC-related inspections

Engineering evaluations

Gap and flush analysis

Customized inspection setups

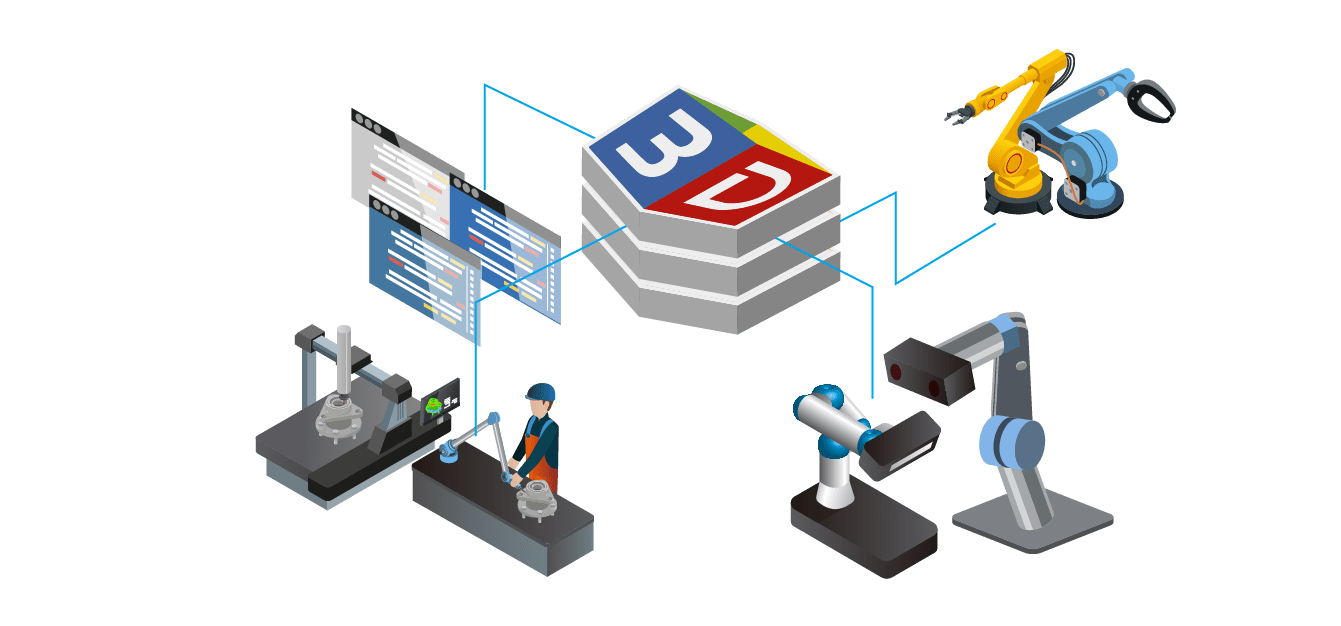

Universal Metrology Automation®

Automated Factory Inspection

The Universal Metrology Automation® (UMA) is used for inspection in factories that are looking to remove the bottleneck of quality control in production processes.

Blue Light Scanning

3D Infotech’s Universal Metrology Automation platform allows the use of a variety of structured light scanners. Our systems support scanners from many different hardware manufacturers. Depending on the customer's part complexity, surface finish and size, 3D Infotech can guide in the selection of the right 3D scanner.

Each scanner has its own data capture software utility. 3D Infotech has invested in directly integrating each scanner into its Streamline software. Within Streamline, the operator has the option to select a scanner type and data capture settings appropriate for that scanner. Whether you are scanning large aerospace parts, medium size automotive parts or small electronic components, 3D Infotech can assist in identifying the right structured light scanner. For highly reflective surfaces, blue light scanning is supported.

Rapid Deployment

With the emergence of robotics and motion control systems, most inspection processes can be automated. Companies that are aware of these technological advancements are eager to deploy automated systems, but they don’t know where to begin. Additionally, the selection of the right hardware and software is confusing and time-consuming. This can often lead to frustration and cost over-runs.

3D Infotech’s UMA is the perfect answer that enables customers to be up and running in a matter of days versus months or years. Simply configure and deploy proven solutions, rather than spend hundreds of hours programming custom systems, which may be like running an experiment.

Laser Scanning

With laser scanning, real-time high-speed data capture is possible while the part or robot is moving. This can be extremely advantageous in certain manufacturing environments. Data can be visualized and sorted as it’s being collected, offering certain advantages over other methods of 3D scanning.

3D Infotech works with a variety of laser scanners, both red and blue, for measuring details on small parts as well as large surfaces. Typically, blue lasers are used for measuring details such as flush & gap, dimensions on circuit boards, and even detection of flaws in the surface finish. An array of red lasers can also be deployed to reduce overall scanning time for larger objects.

UMA Extended Systems

When a UMA Ready solution is not enough for your project, Streamline supports additional modules that extend the features and hardware supported.

Extended systems support the following features:

- Multiple 3D sensors (arrays or different technologies and field of view)

- Multiple motion control devices (rotary tables, linear rails, grippers)

- Machine Vision and Photogrammetry

- Enterprise Database Integration (ERP, QMS, PLM)

- PLC Integration

- Adaptive Manufacturing (grinding, scribing, deburring and drilling)

- Safety Area Scanners and Laser Curtains

- Automated Calibration

- Optical CMM Probing

- Alerts and Notifications

Do you want to know more about the software that powers our Universal Metrology Automation solutions?

Read about how we use and collect your data in our Privacy Policy