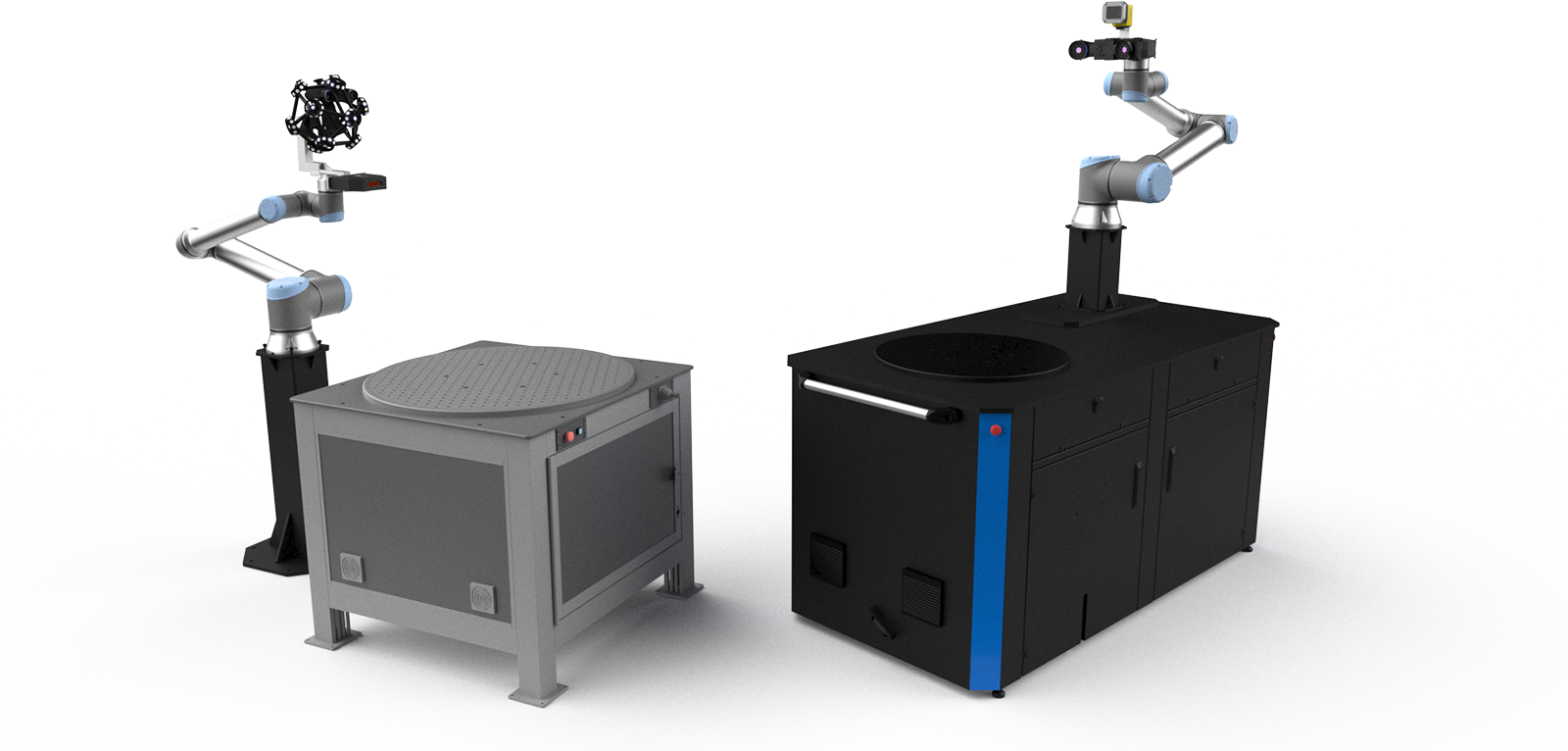

One System - Multiple Inspections

Dual Sensor Inspection Systems brings the best of two worlds to the quality control processes. Combine different inspection technologies to achieve the final results without the limitations of a single sensor.

Bypass the limitations imposed by traditional systems by combining the best capabilities of 2D and 3D sensors. It will also let you execute different inspections in the same station.

Streamline Inspection Automation software handles the process, sensors, robots, rails, and rotaries in a seamless inspection.

Multisensor systems save time, space, and money by delivering a single inspection area for different stages of the manufacturing process.

Acquire different type of data at the same time

Pair a 2D camera with a 3D sensor to get a full 3D scan and other non-dimensional data like barcodes, numbers, engravings, or even cracks and various surface defects.

Micrometric precision with different Field of Views

There is a direct relationship between the field-of-view of a 3D scanner and the area and accuracy it can get. Sometimes you need fast speed for broad surfaces with good resolution, but you also need to get tiny features in specific areas. Combining two different optics can give you the detail you need in small areas that are impossible to reach for your primary 3D scanner.

Save money by combining two inspection stages

Leverage the flexibility of a robotic inspection system by adding a second sensor. Double your inspection capabilities by retaining the investment in hardware and while just adding more vision sensors.

Contact our metrology experts, they will be glad to help you find the best solution for your industry

Let us help you choose the right combination.

Different parts need unique solutions. We analyze your challenge to find the perfect match of hardware and software. It can be as simple as reading a barcode before scanning or as complex as 3D scanning and bore inspection.

3D Infotech has experience with various 2D and 3D sensors choosing the most reliable brands to integrate with our software Streamline.

3D Infotech has experience with various 2D and 3D sensors choosing the most reliable brands to integrate with our software Streamline.

Benefits of multisensor configurations

Add Speed and Flexibility

Go beyond the limitations of single sensor inspection.

The lack of the perfect sensor can limit the adoption of 3D scanning and machine vision. No one sensor can do everything simultaneously, but you can combine multiple sensors to achieve your goals in one system without compromise.

Everything you need in one system

Simplify your workflow

When trying to address different types of inspections for the same part, one of the most time-consuming things can be moving from station to station. It requires not only more time; it needs more hardware, fixtures, people, and space.

When trying to address different types of inspections for the same part, one of the most time-consuming things can be moving from station to station. It requires not only more time; it needs more hardware, fixtures, people, and space.

Contact our metrology experts, they will be glad to help you find the best solution for your industry