Industry 4.0 | Universal Metrology Automation® on the Industrial Internet

With over 500 factories around the globe, GE is ushering in a new era in manufacturing by merging hardware and software and reimagining how products are designed, made and serviced. GE is leading this charge with Brilliant Factories, a sophisticated factory that combines lean manufacturing, advanced and additive manufacturing with advanced software analytics to enhance productivity.

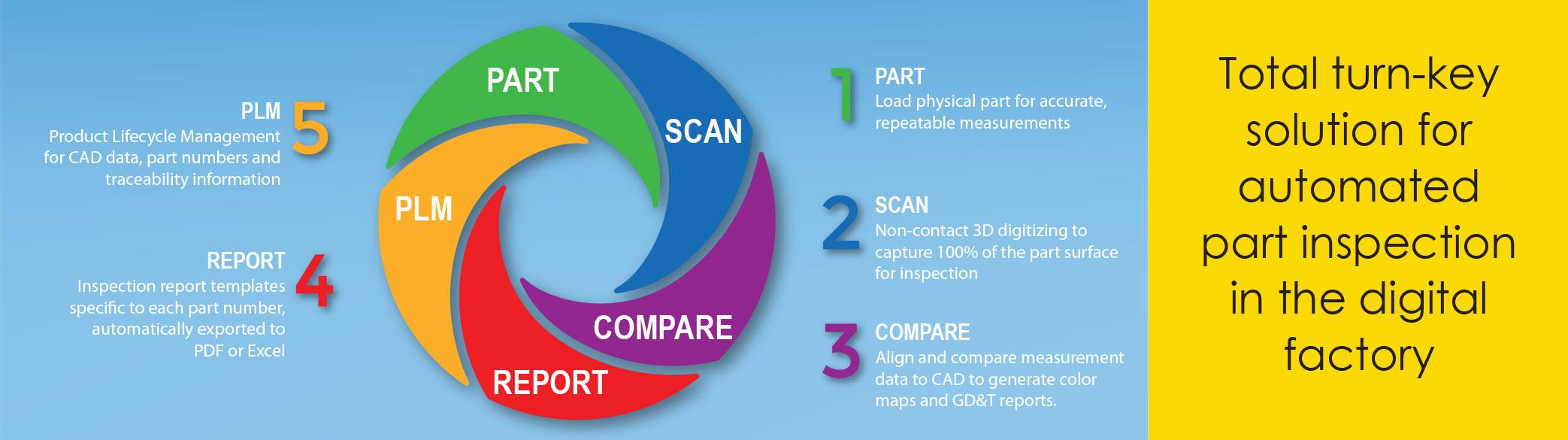

The GE – Brilliant Factory Digital Lab uses data and analytics to transform factories into places that are constantly improving their operations and output. Here, Streamline - Universal Metrology Automation software from 3D Infotech ties 3D coordinate measurement technology, robotic control, and process control applications into one digital cloud. The divide between the lab and the factory, in particular, disappears with the ability to stream data over secure links to improve quality control and manufacturing in a single-source software.

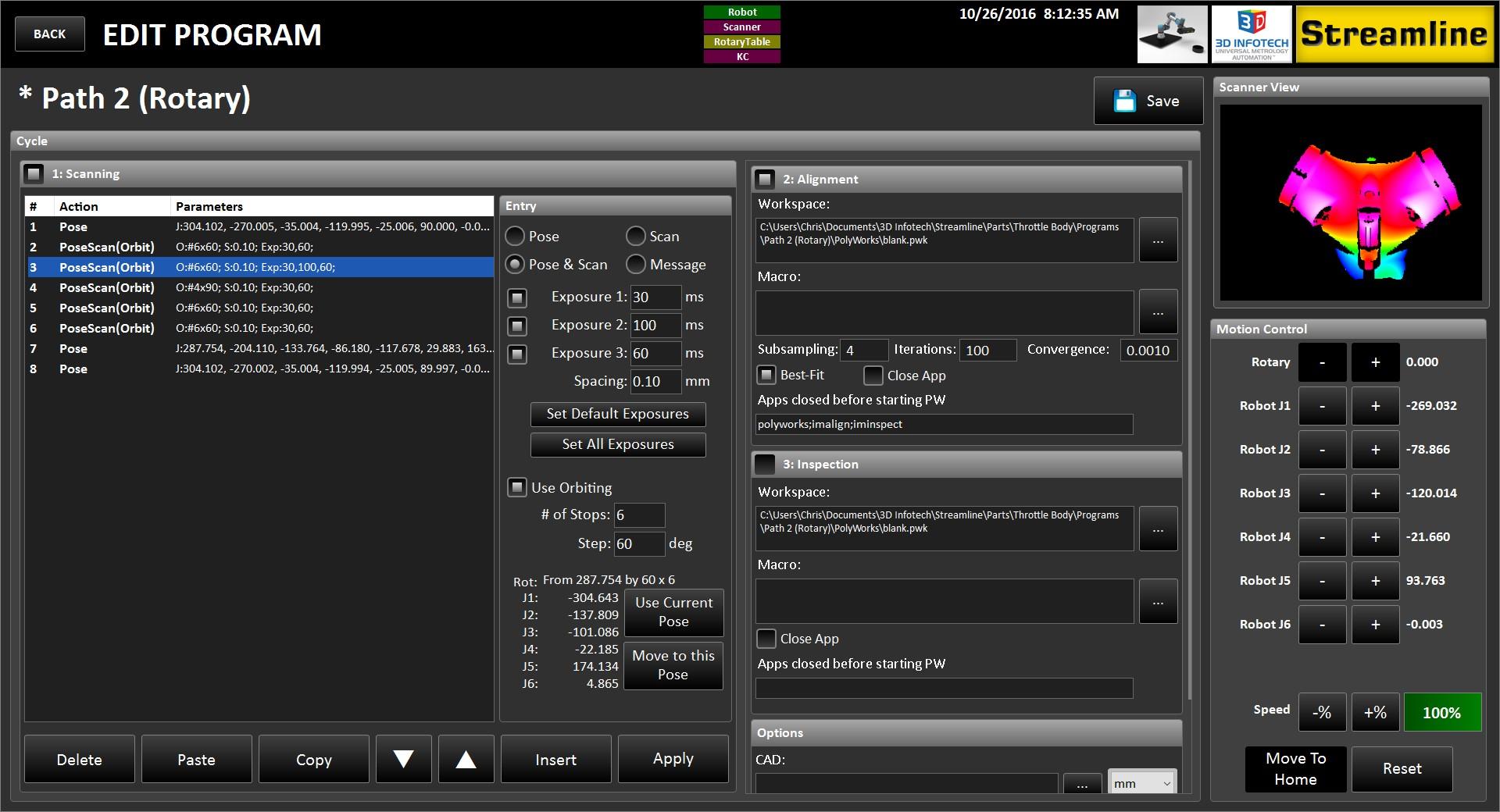

Streamline – Process Control Software

3D Infotech’s Streamline process control software is the soul of Universal Metrology Automation. It allows you to easily setup new automated inspection jobs with a variety of robot and scanner brands. A touchscreen user interface provides a friendly solution which is secure and permission-based. The beauty of Streamline lies in the user-friendly interface. With no prior experience to handling robots or motion control systems, an operator can easily run a program that will move the robot to preset positions, initiate the scanner to capture 3D point cloud data at these positions, and nish the process with a full inspection.

"The digital age will provide manufacturing insights that will save money and transform how we work across supply chains."

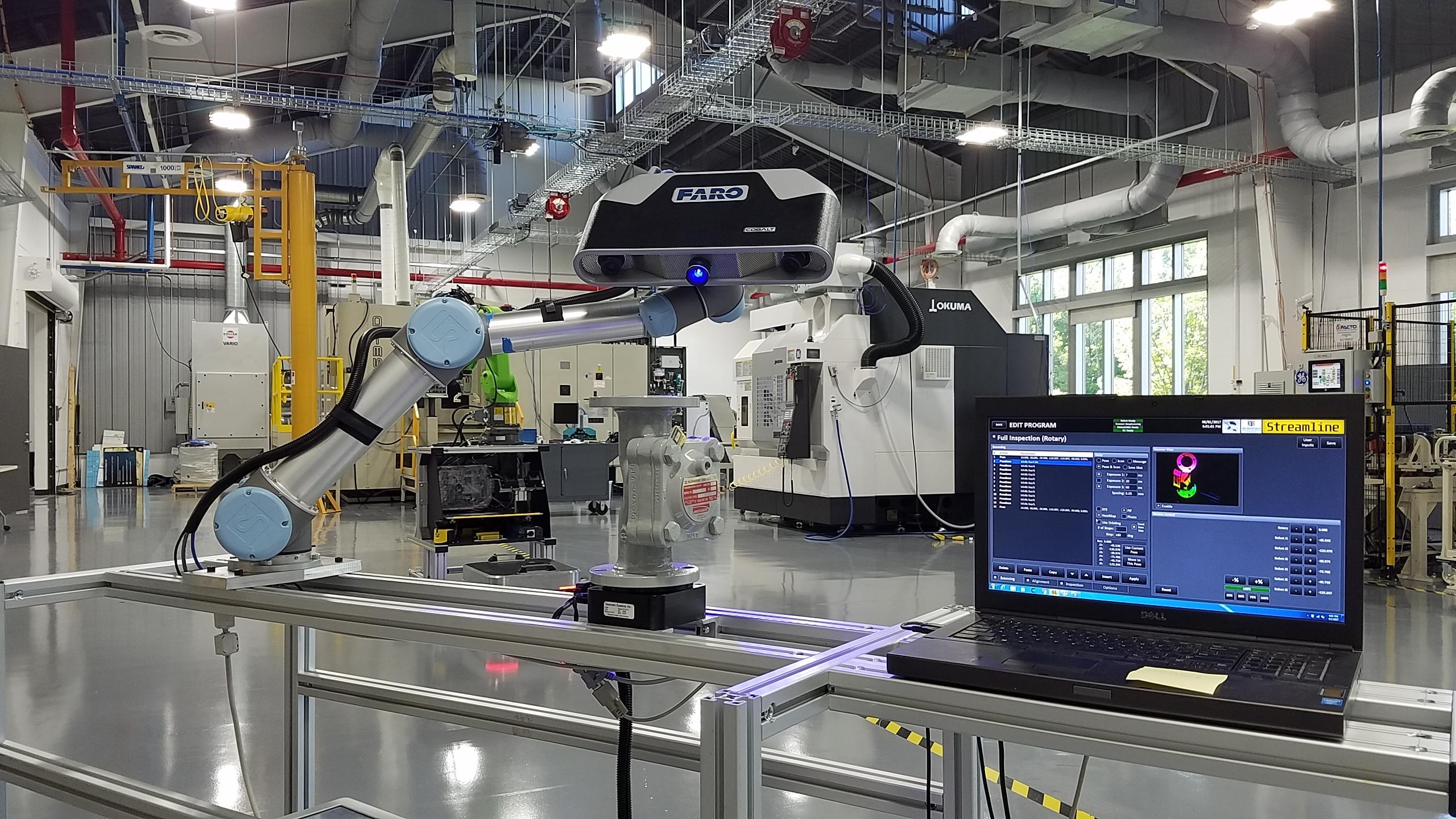

Below is the current setup at GE Global Research in Michigan, USA. Their mobile configuration lets the system to be moved to where it is needed most. Ease of access, durability, and safety are all considered when deploying a new Streamline solution. Within the month of purchasing the hardware, 3D Infotech was able to deploy and provide training for the system. Mosa Mohammad, an Advanced Manufacturing Engineer at GE Global Research, is currently using the system to rapidly scan new parts and test them against the CAD model.

In the past, Mosa has been using a CMM to inspect his 3D printed parts. When we first meet him, he was struggling with setting up the CMM, installing new fixtures, and just plain fed up with the time it would take to inspect one part. With our help, Mosa was able to speed up his inspection time, increase productivity, and free up his own personal time to work on other units that needed his attention.

"I was able to reduce inspection time, increase productivity and free up time for innovation."

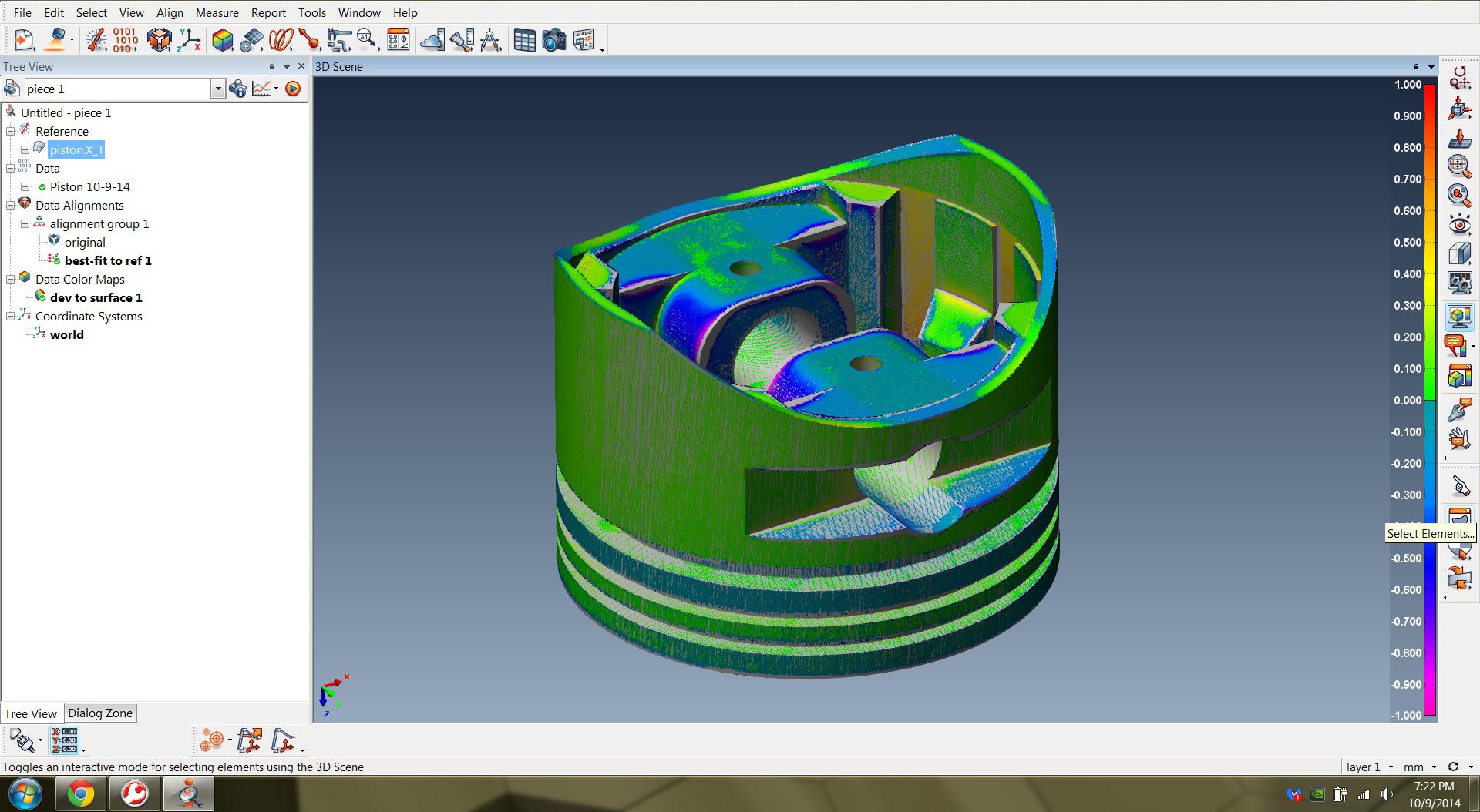

The Best of Both Worlds Streamline & PolyWorks

Behind 3D Infotech’s Streamline software is Innovmetric’s inspection software, PolyWorks. PolyWorks is the industry-standard 3D metrology toolbox for product engineering, assembly guidance, and nal inspection. As the master distributor in the west coast, 3D Infotech provides PolyWorks with every installation of Streamline. With both of these tools now at GE’s disposal, Mosa is now able to accurately determine the integrity of his parts, while having peace in mind of using a trusted inspection software known in the industry.

7 Hubble, Irvine, CA 92618, USA

Tel +1 (949) 988-0200 Fax +1 (949) 417-2657

www.3dinfotech.com