Quick Inspection of small OD formed tubing

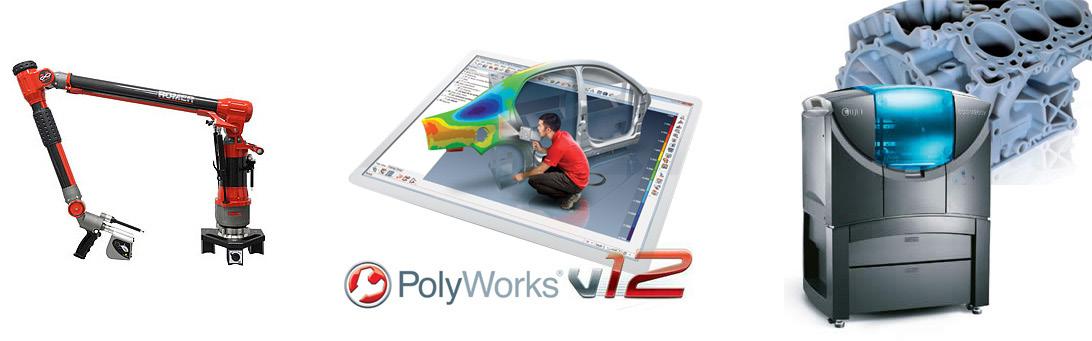

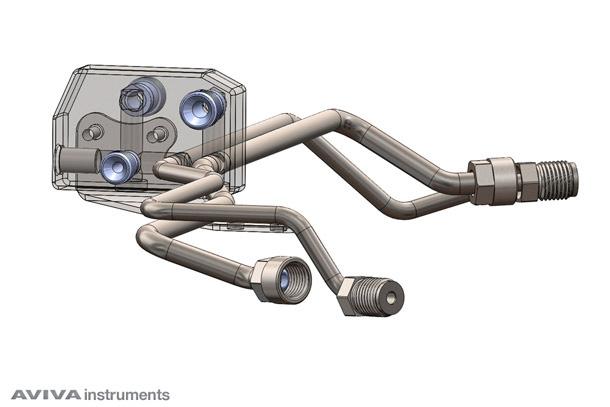

One of the main subsystems for our product is a complex assembly of stainless steel machined parts, and stainless steel formed tubing. Combining to form a fuel delivery & return manifold for the direct injection fuel system. The nature of the design and the work envelope of the project restricted the design to uncomfortably tight tolerances. Quick Inspection of small OD formed tubing. As such every part had to be inspected and verified prior to final assembly of the fuel manifold, as individual component errors would be magnified in the finished product once fully assembled.

With Polyworks V12 and the Romer Infinite 2.0 equipped with a perceptron scan shark, tubing inspection and error mapping only took a few mins per part, compared with hours with traditional CMM probing methods. No fixture was needed, only a simple plastic jawed vice. The results where very easily displayed, critical faces and their delta from nominal could be identified with only a quick look at the color mapping.

A few advantages:

- Very easy to communicate non conformity and results with vendors and employees responsible.

- Quickly inspect an entire production run, rather than a representative sample, in even less time than traditional probing of a single piece.

- Inspect single components, or the entire assembly.

Items Featured:

- [ HPMFS ] High-Pressure Fuel Management System for the Aviva 4.2L FSI TVS SC System

- Designed to deliver increased fuel volume to and from fuel pumps

- Clearance to accommodate the large air-water inter-cooler system

- 3D CNC machined stainless steel fuel manifold

- CNC mandrel bend stainless steel fuel lines

Tech Featured:

- Romer V4 Scan shark laser line probe

- Poly-works V12 powered inspection

- Object Rapid prototype

New high-pressure fuel lines are required for the RS4 SC System. The design and mfg process involves tight tolerances and multiple inspections at various points to ensure proper performance, fit, and safety.

Many iterations between design considerations, mfg possibilities, mfg processes, assembly order were needed to reach this final state.

Pictured:

7 Hubble, Irvine, CA 92618, USA

Tel +1 (949) 988-0200 Fax +1 (949) 417-2657

www.3dinfotech.com